4 Cavilities Full Automatic Bottle Molding Machine

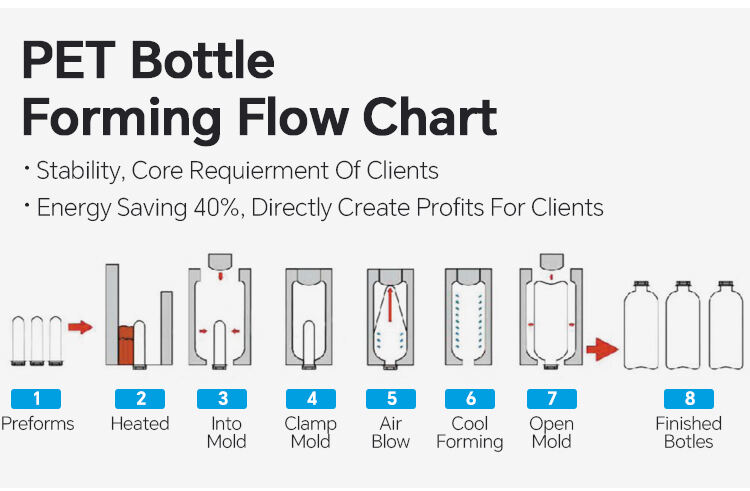

In the growing and competitive beverage and juice industry, the packaging process is not only the final step, but also a key factor affecting product appeal, shelf life and brand value. Our PET automatic blow molding machine will disrupt the industry landscape, integrating cutting-edge innovative technologies, intelligent automation and sustainable development features to redefine the standard of preform production for modern beverage manufacturers.

1. Innovative technology, breaking the boundaries of performance

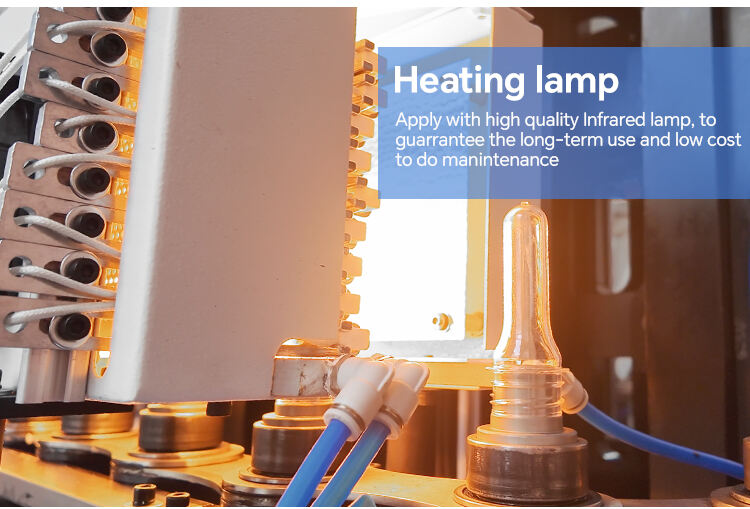

This PET automatic blow molding machine is equipped with a revolutionary hybrid heating-stretching-blowing system. This integrated system combines the advantages of different heating methods such as infrared and hot air circulation to achieve fast and uniform heating of the preform. The intelligent heating control module can analyze the material properties, size and production speed of the preform in real time, and adjust the heating intensity and heating time according to each preform. As a result, the heating efficiency is improved by 30%, and the energy consumption during the heating process is significantly reduced.

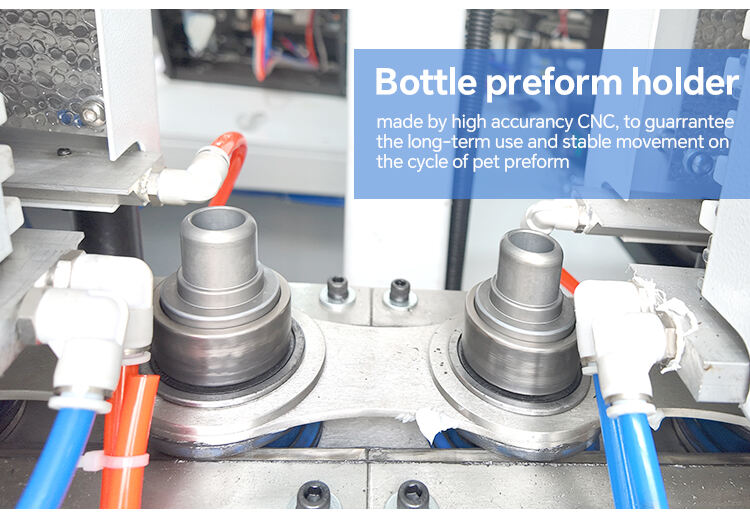

The stretching mechanism adopts a variable speed and variable force design. Unlike traditional fixed parameter stretching, our machine can adjust the stretching speed and stretching force according to the specific requirements of the bottle design. For example, when producing thin-walled or complex-shaped bottles, the stretching process can be fine-tuned to ensure that the plastic is evenly distributed to avoid thinning or breakage. This precise control of the stretching process enhances the mechanical properties of the bottle, with 25% higher impact resistance and 20% higher tensile strength than bottles produced by conventional machines. The blow molding unit uses a high-pressure and high-flow air supply system. During the blow molding process, the air pressure and flow can be precisely adjusted to produce bottles with precise dimensions and smooth surfaces. The unique air cooling design of the mold helps the plastic solidify quickly, shortens the cooling time by 20%, and improves the overall production cycle.

2. High efficiency and energy saving, leading green production

Our PET fully automatic blow molding machine is designed for large-scale production, with an output of up to [X] bottles per hour, depending on the size and complexity of the bottle. From preform loading to bottle unloading, the fully automatic production line is seamless. The high-speed preform feeding system can process [X] preforms per minute, ensuring a continuous material supply for the heating and blowing processes.

Energy saving is the focus of our machine design. Servo-driven components, such as the clamping system, stretching mechanism and conveyor belt, consume only the necessary power. Compared with traditional hydraulic-driven machines, our PET fully automatic blow molding machine can reduce energy consumption by 40%. In addition, the waste heat recovery system can recover the heat generated during heating and cooling and use it for plant preheating or other auxiliary operations, further improving overall energy efficiency.

The modular and compact design of the equipment also helps save space in the production workshop. Compared with similar models, it has a smaller footprint and can be easily integrated into existing production lines, maximizing the use of factory space and reducing the cost of factory layout adjustments.

| TechnicalParameters | ZPA-1L-2 | ZPA-2L-2 | ZPA-1L-4 | ZPA-2L-4 | ZPA-1L-6 | ZPA-2L-6 | |

| Cavity | 2 | 2 | 4 | 4 | 6 | 6 | |

| Host Machine Parameter |

Clamping Force | 35000 | 45000 | 48000 | 48000 | 56000 | 65000 |

| Mold Route | 90 | 110 | 90 | 125 | 90 | 125 | |

| Stretching Rod Route | 300 | 400 | 260 | 330 | 260 | 330 | |

| Boctomn llold Route | 50 | 50 | 50 | 50 | 50 | 50 | |

| Bottle Spacing | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | |

| Bottle Preform Number | 66 | 52 | 95 | 82 | 106 | 92 | |

| Prodncts Parameter |

Max Capacty | 660 | 1500 | 600 | 1500 | 600 | 1500 |

| Max Bottle Boby Height | 260 | 330 | 260 | 330 | 260 | 330 | |

| Max Bottle Body Diameter | 68 | 105 | 68 | 105 | 68 | 105 | |

| MaxBottle Preformn Height |

100 | 140 | 100 | 140 | 100 | 140 | |

| Max Bottle Mouth Diameter |

38 | 38 | 38 | 38 | 38 | 38 | |

|

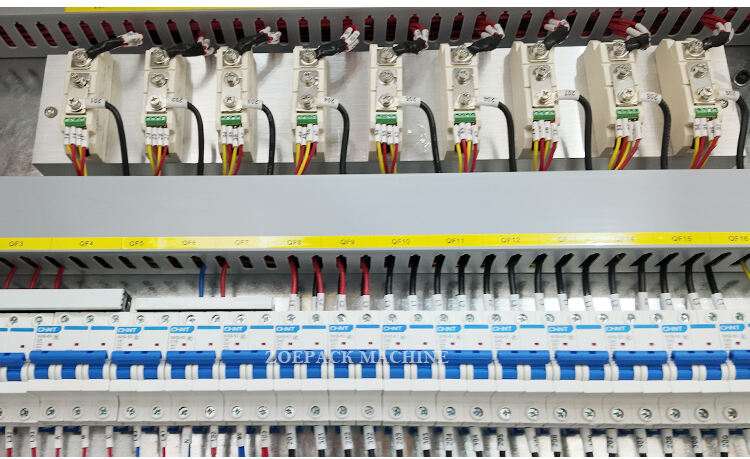

Eleetrical Parameter |

Capacty | 2500 | 2000 | 4500 | 4000 | 7200 | 6000 |

| Heating Oven Quantity | 2*2 | 4*4 | 4*4 | 5*5 | 4*4 | 5*8 | |

| Heating Lamp Quantity | 2*8 | 4*8 | 4*7 | 5*9 | 4*8 | 5*9 | |

| Heating Confguration Power | 32 | 48 | 42 | 72 | 64 | 90 | |

| Total Power Capedity | 32 | 48 | 42 | 72 | 64 | 90 | |

| Voltage | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | |

| Air source Parameter |

Worling Pressure | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| Blowing Pressure | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | |

| Air Capacitly Consumption | 2.4/30 | 2.4/30 | 3.6/30 | 3.6/30 | 5.0/30 | |

| Total Powwer | 30 | 30 | 45 | 45 | 60 | |

| Cooling Chiler Parameter | Ternperature | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 |

| Pressure | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Rated Power | 3 | 3 | 5 | 5 | 5 | |

| Dimenson | Host Machine Size | 2700*1800 | 3300*1800 | 3900*1800 | 4800*2200 | 4200*2100 |

1 .stable and accurate running at high speed,adopt more stable and advanced micro-computer PLC control system.

2. production process is fully automated, with the advantages of low investment, highefficiency,easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range ofapplications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control. simple operation.

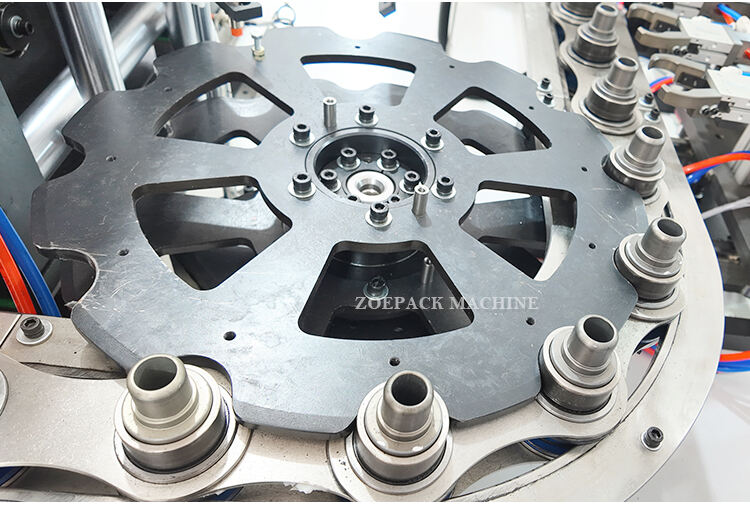

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle.