Открийте Чудесата на 4 Кавитетна Пълно Автоматична Машина за Молдинг на Бутилки

Индустрията по производство на пластмасови бутилки постоянно се развива, и да останем напред изисква прилагането на най-новите технологии. 4 Кавитетната Пълно Автоматична Машина за Молдинг на Бутилки е революционно устройство, което предлага множество предимства на производителите, от повишена продуктивност до превъзходно качество.

Потребителски Интерфейс за Безпроблемна Операция

Сензорната цветна HMI система на тази машина е отличителна черта. Тя включва графично представяне на производствения процес, което улеснява операторите да визуализират всеки стъпка. Например, дисплеят показва 3D модел на бутилката, която се формира, с реално-времеви индикатори за температура, притиск и поток на материал. Това визуално обратно връзки помага операторите бързо да идентифицират всяка проблем и да направят необходимите корекции. Системата също разполага с вградена функция за помощ, която предоставя подробни обяснения за всеки контрол и параметър. Дали операторът е новачък или изкушен професионалист, те могат лесно да достъпят информацията, която им трябва, за да управляват машината ефективно.

Производство с висока капацитет с непоколебима последователност

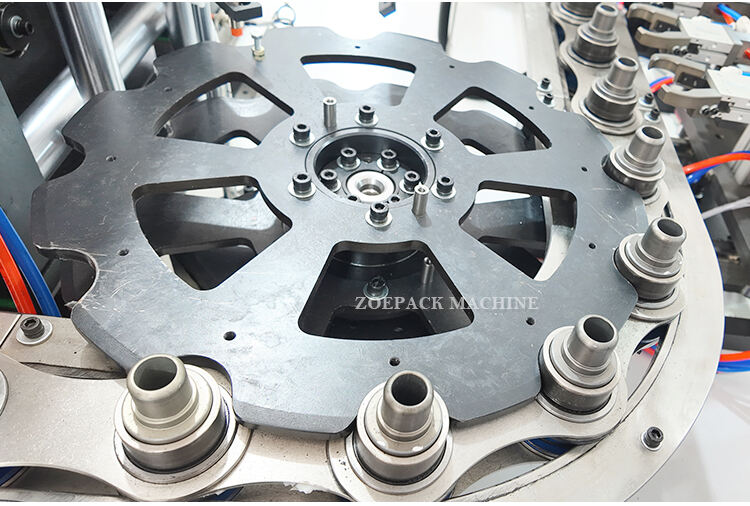

Четирикамерният дизайн на машината позволява високопроизводително произвеждане без да се жертвува качеството. Всяка камера е укомплектована със собствен набор от датчици и контроли, които гарантират, че всеки производен бутилкя отговаря на същите високи стандарти. Продвинатата система за управление на машината координира операцията на всички четири камери, оптимизирайки процеса на производство за максимална ефективност. Максималната скорост на производство от 1500 бутилки на час се постига чрез комбинация от високоскоростни механични компоненти и интелигентни софтуерни алгоритми. Софтуера постоянно проследява производствения процес и коригира параметрите в реално време, за да осигури гладко и последователно функциониране. Това води до високопроизводителен изход от бутилки с еднородно качество, намалявайки нуждата от разширени проверки след производството.

Версатилност за удовлетворяване на различни упакователни изисквания

Съвместимостта на машината с всички видове бутилки от PET я прави подходяща за широк спектър от индустрии. В фармацевтичната индустрия тя може да произвежда бутилки с конкретни изисквания за стерилност и безопасност. Чисто-стаятна конструкция на машината гарантира, че производствената среда отговаря на строгите стандарти на фармацевтичната индустрия. Системата за бърза смяна на формите позволява производството на различни размери и форми на бутилките, което дава възможност на производителите да упаковат различни лекарства, от малки таблетки до големи течни формули. Тази универсалност прави машината ценен актив за всеки производител, който иска да разшири своя асортимент и да удовлетвори различните нужди на клиентите си.

Прецизно изградена за премиум бутилки

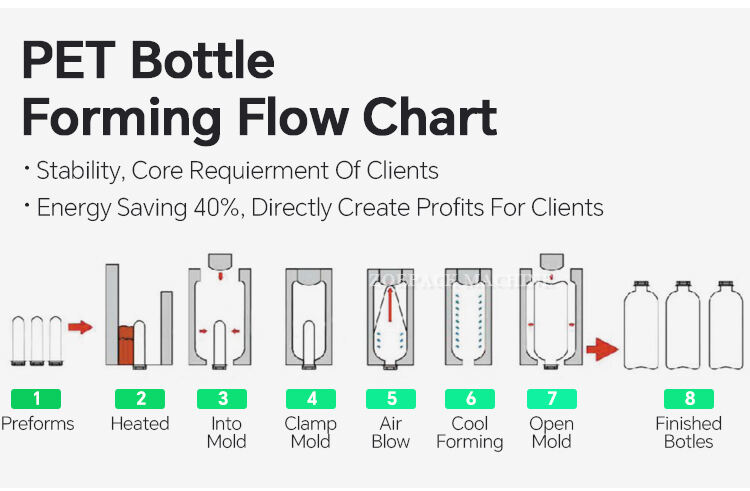

Качеството е в сърцето на конструкцията на тази машина. Екструзионната система използва високопrecизен шумен дизайн, който гарантира равномерно разтопяване на материалът PET. Това води до консистентен поток на материала, което е необходимо за производство на бутилки с равномерна стена. Процесът на дуване се контролира чрез регулатор с висока точност за притискание, който поддържа постоянно въздушно притискание по време на надуването на пластмасовия парисон. Тази прецизност гарантира, че бутилките се формират с точно зададената форма и размери. Машината също разполага с вградена система за контрол на качеството, която проверява всяка бутилка за дефекти, като протечки, тресове или неравномерни повърхности. Всички дефектни бутилки се премахват веднага от линията за производство, гарантирайки, че само продукти с най-високо качество достигат клиентите.

Енергийно ефективно и устойчиво производство

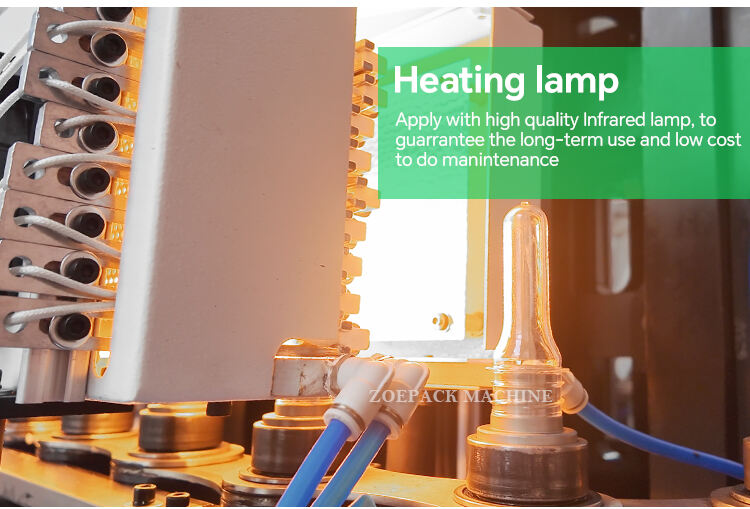

В епоха на растящата екологична съзнателност, тази машина е проектирана с енергосъхраняващи функции, които намалят нейния углероден след. Интелигентната система за отопление използва променливочестотен привод, за да регулира мощността на отоплението според производствените нужди. Това намалява употребата на енергия до 30% в сравнение с традиционните системи за отопление. Системата за охлаждане също е проектирана да бъде енергоефективна, използвайки нискоенергийен вентилатор и топлообменик за разсеване на топлината, генерирана по време на производствения процес. Освен това, машината е направена от переработими материали, което допринася още повече към нейната устойчивост.

Изключителен следпродажбов услуга за спокойствие

Нашето следпродажно обслужване е разработено, за да предоставя на нашите клиенти спокойствие. Предлагаме гореща линия за техническа поддръжка 24/7, където нашият отряд от експерти е наличен, за да отговори на всички въпроси или да реши всяка проблема. Предоставяме също обучение на място за новите оператори, което гарантира, че те са напълно обучени и сигурни в употребата на машината. Нашите регуларни услуги за поддържане включват всеобхватна проверка на всички компоненти, замяна на износените части и калибриране на сензорите. Това профилактично поддържане помага да се запази машината в оптимално състояние и намалява риска от аварии. Освен това предлагаме услуга за инвентаризация на запасите от запчастите, което гарантира, че нашите клиенти могат бързо да получат необходимите им части в случай на авария.

Подводейки, 4-кавитетната пълноавтоматична машина за формиране на бутилки е впечатляващо устройство, което предлага широк спектър от предимства за производителите. Благодарение на потребителският си интерфейс, голямото обемно производство, многофункционалността, прецизно качество, енергоефективния дизайн и изключителното следпродажно обслужване, тя е идеалният избор за всеки производител, който иска да подобри своя производствен процес и да остане напред в конкурентната индустрия по производство на пластмасови бутилки. Свържете се с нас днес, за да откриете чудесата на тази невероятна машина.

1. Устойчиво и точно функциониране на висока скорост, придобива по-устойчива и продвината микрокомпютърна PLC контролна система.

2. производственият процес е напълно автоматизиран, с предимства като ниска инвестиция, висока ефективност, лесна операция, проста поддръжка и безопасност.

3. подходящ за гъвкаво производство с различни количества и форми на бутилки, широк диапазон от приложения, отговарящ на нуждите на клиентите.

4. ръчни и автоматизирани методи на операция, контрол чрез човеко-машинен интерфейс.

просто управление.

5. сервоприводна система за трансмисия, висока точност на позиционирането, бърза скорост и стабилност, добри надеждност.

6. отпадъците за готовите бутилки са по-малко от 0.2%.