In the ever - evolving landscape of the beverage and juice packaging industry, the Semi - Automatic PET Beverage Juice Bottle Blow Molding Machine has emerged as a crucial piece of equipment. This machine is designed to meet the specific needs of producing high - quality PET bottles that are ideal for packaging a wide range of beverages and juices.

1. Understanding the Basics of PET Bottle Production

PET (Polyethylene Terephthalate) has become the material of choice for beverage and juice bottles due to its excellent properties. It is lightweight, transparent, strong, and has good barrier properties against oxygen and moisture, which helps to preserve the quality and freshness of the beverages and juices inside.

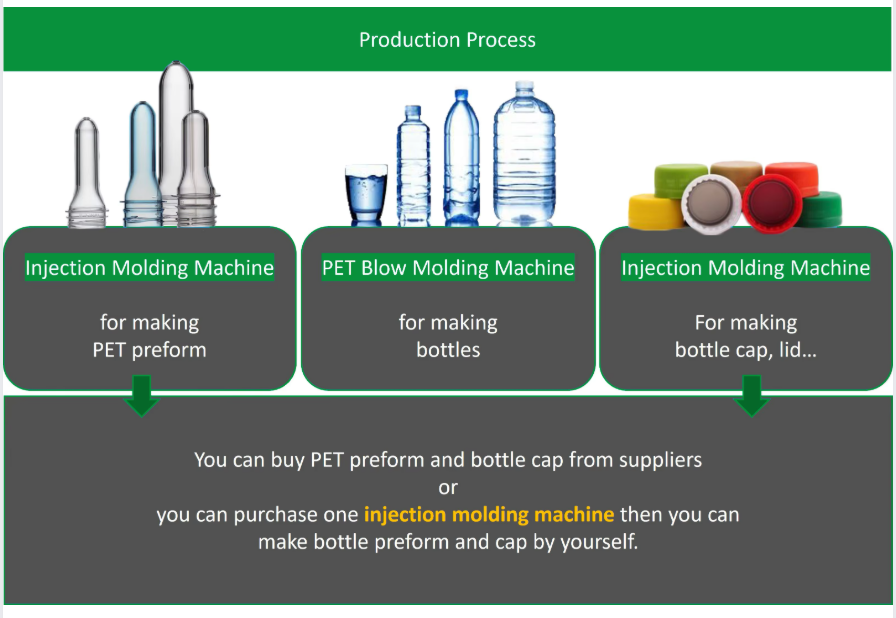

The process of producing PET bottles typically involves two main steps. First, preforms are created through an injection - molding process. These preforms are small, tube - like structures with a threaded neck. Then, the preforms are transformed into the final bottle shape using a blow - molding machine. This is where the Semi - Automatic PET Beverage Juice Bottle Blow Molding Machine comes into play.

2. Features of the Semi - Automatic PET Beverage Juice Bottle Blow Molding Machine

2.1 Operational Flexibility

One of the key advantages of a semi - automatic machine is its flexibility. It allows for a certain level of manual intervention, which can be beneficial for small - to - medium - scale producers or those who need to produce a variety of bottle sizes and shapes. Operators can closely monitor and adjust the production process as needed. For example, when switching between different bottle designs, the operator can manually load the appropriate molds and make necessary adjustments to the machine settings, such as the blowing pressure and temperature. This flexibility is not as easily achievable in fully automated machines, which are often optimized for high - volume production of a single bottle type.

2.2 Cost - Effectiveness

Semi - automatic machines are generally more cost - effective to purchase and operate compared to their fully automated counterparts. The initial investment required for a semi - automatic PET bottle blow - molding machine is lower, making it an attractive option for startups or businesses with limited budgets. Additionally, the energy consumption of these machines is relatively moderate. They don't require the same level of high - powered automation systems that consume large amounts of electricity. This lower energy consumption not only reduces the operating costs but also makes the machine more environmentally friendly.

2.3 Quality Control

Despite being semi - automatic, these machines are designed to ensure high - quality bottle production. The heating system, for instance, is carefully engineered to evenly heat the PET preforms. Most semi - automatic machines use infrared ovens, which provide a consistent and controlled heat source. As the preforms are rotated during the heating process, each part of the preform is uniformly heated. This even heating is essential for achieving a consistent wall thickness in the final bottle. A consistent wall thickness ensures that the bottle has the necessary strength to withstand the pressure of the filled beverage or juice and also contributes to an aesthetically pleasing appearance.

2.4 Ease of Maintenance

Semi - automatic PET bottle blow - molding machines are relatively easy to maintain. Their mechanical components are often more straightforward compared to complex automated systems. For example, the mold - adjusting mechanism in many semi - automatic machines is designed to be simple and accessible. This simplicity makes it easier for maintenance staff to perform routine checks, clean the machine, and replace any worn - out parts. In addition, the machine's lubrication system is typically designed for easy operation, with some models having an oiling system that can be easily monitored and refilled. This ease of maintenance helps to minimize downtime, ensuring that the production process can continue smoothly.

2.5 Safety Features

Safety is a top priority in the design of these machines. They are equipped with various safety features to protect the operators. For example, the machine may have safety guards around the moving parts, such as the mold - closing mechanism. These guards prevent the operator from accidentally coming into contact with the machinery during operation. Additionally, emergency stop buttons are strategically placed on the machine, allowing the operator to quickly halt the machine in case of any unexpected situations. Some machines also have sensors that can detect if the preforms are not properly loaded or if there is an issue with the heating or blowing process, and they will automatically stop the machine to prevent any damage or safety hazards.