4 Cavilities Full Automatic Bottle Molding Machine

In the competitive and dynamic beverage and juice industry, packaging machinery is the cornerstone of transforming innovative product ideas into marketable masterpieces. As a technological pioneer, our PET automatic blow molding machine integrates breakthrough engineering technology, intelligent automation and sustainable solutions to raise the bar in beverage packaging production.

1. Process innovation, opening a new era of precision manufacturing

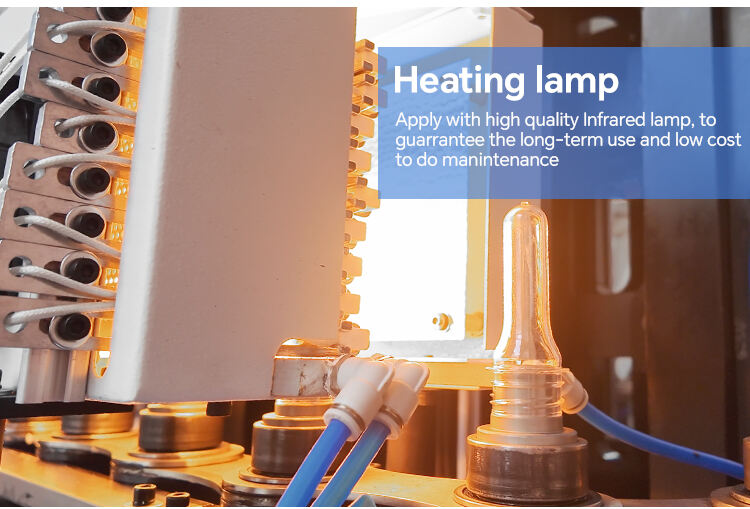

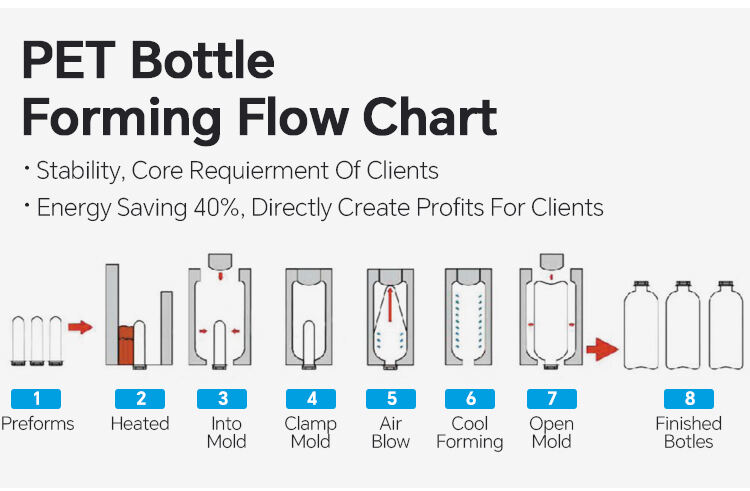

The core of our PET automatic blow molding machine is a revolutionary multi-zone heating and stretching process. The preform heating section is divided into multiple independent temperature control zones, each of which is precisely calibrated to heat different parts of the PET preform according to the specific requirements of the PET preform during the blowing process. This fine zoning control ensures uniform softening of the preform, eliminating hot and cold spots that may cause uneven thickness or structural defects in the final bottle wall.

The stretching mechanism has been redesigned and equipped with a dynamic feedback control system. High-precision sensors continuously monitor the stretching force and speed, and the system adjusts these parameters in real time according to the characteristics of the preform and the required bottle specifications. For example, when producing bottles with complex curves or sharp edges, the stretching process can be fine-tuned to ensure that the plastic is precisely deformed as required, thereby producing bottles with stable quality and beautiful appearance. This advanced control system has been shown to reduce defect rates by 22% compared to traditional stretching mechanisms. The variable pressure air injection system enhances the performance of the blow molding stage. It can apply different levels of air pressure at various stages of the blow molding process. First, gentle pressure is used to form the basic shape of the bottle, and then higher pressure is applied to ensure that the details of the bottle, such as logos and text embossing, are clear and sharp. This variable pressure method not only improves the appearance quality of the bottle, but also optimizes the material distribution, making the bottle both light and durable.

2. Intelligent upgrade to create a new paradigm of efficient production

Our PET automatic blow molding machine is at the forefront of industrial intelligence. It integrates an advanced artificial intelligence (AI) control system that can learn from past production runs and continuously optimize its operation. The AI system analyzes a large amount of data, including production speed, material consumption, and quality control results, to identify patterns and make predictive adjustments. For example, it can predict changes in material properties caused by environmental factors and actively modify heating and blowing parameters to ensure uninterrupted production and minimize quality fluctuations.

The machine also uses digital twin technology. It creates a virtual replica of a physical machine, enabling manufacturers to simulate production scenarios, test new bottle designs, and optimize production settings in a risk-free digital environment. The digital twin can be used to train operators, troubleshoot potential problems, and even predict equipment maintenance needs, significantly reducing downtime and improving overall production efficiency.

| TechnicalParameters | ZPA-1L-2 | ZPA-2L-2 | ZPA-1L-4 | ZPA-2L-4 | ZPA-1L-6 | ZPA-2L-6 | |

| Cavity | 2 | 2 | 4 | 4 | 6 | 6 | |

| Host Machine Parameter |

Clamping Force | 35000 | 45000 | 48000 | 48000 | 56000 | 65000 |

| Mold Route | 90 | 110 | 90 | 125 | 90 | 125 | |

| Stretching Rod Route | 300 | 400 | 260 | 330 | 260 | 330 | |

| Boctomn llold Route | 50 | 50 | 50 | 50 | 50 | 50 | |

| Bottle Spacing | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | |

| Bottle Preform Number | 66 | 52 | 95 | 82 | 106 | 92 | |

| Prodncts Parameter |

Max Capacty | 660 | 1500 | 600 | 1500 | 600 | 1500 |

| Max Bottle Boby Height | 260 | 330 | 260 | 330 | 260 | 330 | |

| Max Bottle Body Diameter | 68 | 105 | 68 | 105 | 68 | 105 | |

| MaxBottle Preformn Height |

100 | 140 | 100 | 140 | 100 | 140 | |

| Max Bottle Mouth Diameter |

38 | 38 | 38 | 38 | 38 | 38 | |

|

Eleetrical Parameter |

Capacty | 2500 | 2000 | 4500 | 4000 | 7200 | 6000 |

| Heating Oven Quantity | 2*2 | 4*4 | 4*4 | 5*5 | 4*4 | 5*8 | |

| Heating Lamp Quantity | 2*8 | 4*8 | 4*7 | 5*9 | 4*8 | 5*9 | |

| Heating Confguration Power | 32 | 48 | 42 | 72 | 64 | 90 | |

| Total Power Capedity | 32 | 48 | 42 | 72 | 64 | 90 | |

| Voltage | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | |

| Air source Parameter |

Worling Pressure | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| Blowing Pressure | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | |

| Air Capacitly Consumption | 2.4/30 | 2.4/30 | 3.6/30 | 3.6/30 | 5.0/30 | |

| Total Powwer | 30 | 30 | 45 | 45 | 60 | |

| Cooling Chiler Parameter | Ternperature | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 |

| Pressure | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Rated Power | 3 | 3 | 5 | 5 | 5 | |

| Dimenson | Host Machine Size | 2700*1800 | 3300*1800 | 3900*1800 | 4800*2200 | 4200*2100 |

1 .stable and accurate running at high speed,adopt more stable and advanced micro-computer PLC control system.

2. production process is fully automated, with the advantages of low investment, highefficiency,easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range ofapplications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control. simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle.

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's ZOE PACK's advantage?

ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!