ZOE PACK

Semi Automatic PET Bottle Blow Molding Machine

In the dynamic world of beverage and juice packaging, innovation is the key to meeting the ever - changing demands of consumers and the industry. One such revolutionary piece of equipment is the PET (Polyethylene Terephthalate) Beverage Juice Blow Molding Machine. This machine has transformed the way PET bottles for beverages and juices are produced, offering numerous advantages in terms of efficiency, quality, and versatility.

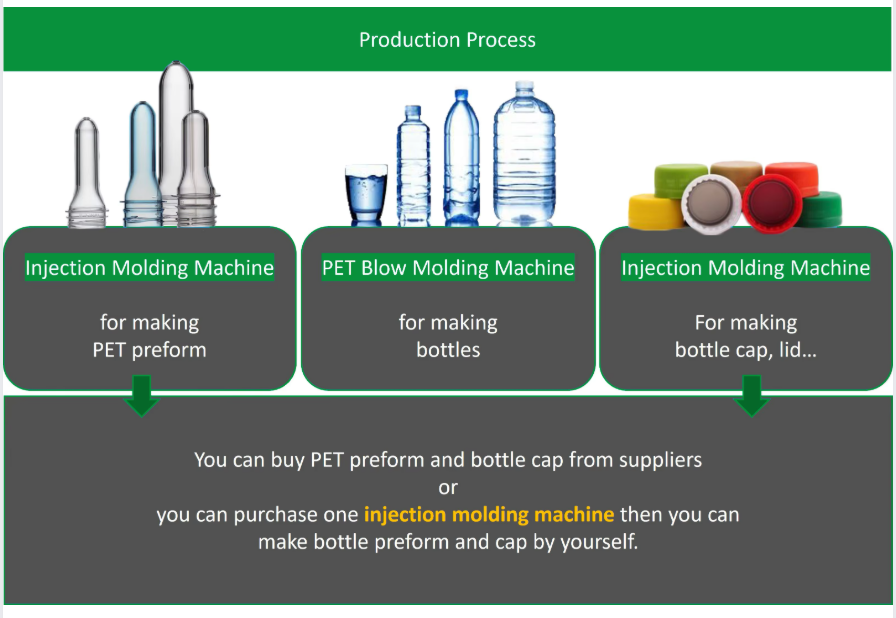

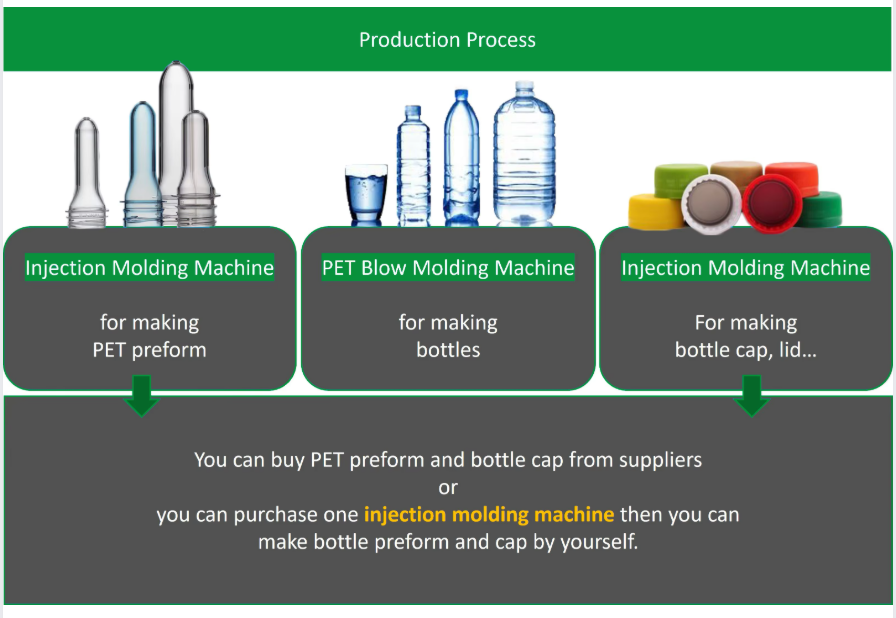

1. Understanding the PET Blow Molding Process

PET blow molding is a manufacturing process used to produce hollow plastic containers, such as bottles. In the context of beverage and juice packaging, the process starts with preforms. These preforms are small, tube - like structures made of PET resin. The preforms are first heated to a specific temperature range where the PET becomes malleable.

Once heated, the preforms are placed into a mold cavity of the blow molding machine. Compressed air is then injected into the preform, forcing it to expand and take the shape of the mold cavity. This results in the creation of a PET bottle with the desired shape, size, and thickness. For beverage and juice applications, the bottles need to be carefully designed to ensure proper barrier properties, strength, and aesthetic appeal.

2. Key Features of PET Beverage Juice Blow Molding Machines

2.1 High - Speed Production

Modern PET beverage juice blow molding machines are engineered for high - speed production. They can produce a large number of bottles per hour, meeting the high - volume demands of the beverage and juice industries. For example, some advanced models can produce thousands of bottles per hour, significantly increasing productivity and reducing production time. This high - speed production is crucial for large - scale beverage and juice manufacturers who need to fill store shelves quickly.

2.2 Precision and Consistency

Precision is of utmost importance in the production of beverage and juice bottles. PET blow molding machines are designed to ensure consistent bottle quality. The temperature control during the preform heating stage is highly accurate, ensuring that each preform is heated uniformly. This results in bottles with consistent wall thickness, which is essential for maintaining the structural integrity of the bottle. Consistent bottle quality also means that the filling process can be more efficient, as all bottles have the same dimensions and properties.

2.3 Versatility in Bottle Design

The PET Beverage Juice Blow Molding Machine offers great versatility in bottle design. Manufacturers can produce bottles of various shapes, sizes, and neck finishes. Whether it's a slender, elegant juice bottle or a standard - sized beverage bottle with a specific neck size for easy capping, the machine can accommodate different design requirements. This versatility allows beverage and juice companies to differentiate their products on the market, creating unique packaging that stands out on store shelves.

2.4 Energy - Efficiency

In an era where sustainability and cost - effectiveness are highly valued, energy - efficiency is a key feature of PET blow molding machines. These machines are designed to minimize energy consumption during the production process. For instance, advanced heating systems use infrared technology to heat the preforms more efficiently, reducing energy waste. Additionally, the use of servo - motors in some models helps to optimize the movement of the machine components, further reducing power consumption. Energy - efficient machines not only lower production costs but also contribute to a more sustainable manufacturing process.

2.5 Hygienic Design

Since the bottles produced are for food and beverage applications, hygiene is a top priority. PET Beverage Juice Blow Molding Machines are designed with hygienic features. The machine components that come into contact with the preforms or the bottles are made of materials that are easy to clean and sanitize. The production area is often enclosed to prevent contamination from the external environment. This ensures that the bottles produced are safe for packaging beverages and juices, meeting strict food safety standards.

3. Applications in the Beverage and Juice Industries

3.1 Bottled Water

PET blow molding machines are widely used in the production of bottled water containers. The transparency of PET allows consumers to easily see the quality of the water inside. The lightweight nature of PET bottles makes them convenient for consumers to carry, whether they are on - the - go or at home. The ability of the blow molding machine to produce bottles with consistent quality ensures that the water remains fresh and uncontaminated until it is consumed.

3.2 Fruit Juices

Fruit juice manufacturers rely on PET bottles for their packaging due to the excellent barrier properties of PET. The blow molding machine can produce bottles that effectively prevent oxygen and moisture from entering, preserving the flavor, color, and nutritional value of the juice for longer periods. The versatility in bottle design also allows juice companies to create attractive packaging that appeals to consumers, highlighting the natural and healthy aspects of their products.

3.3 Soft Drinks

For carbonated soft drinks, the PET bottles produced by blow molding machines need to be able to withstand the internal pressure generated by the carbonation. The PET material, when processed correctly by the blow molding machine, provides the necessary strength and gas - barrier properties to keep the soft drinks fizzy. The high - speed production capabilities of the machine are also well - suited to the large - scale production requirements of the soft drink industry.

3.4 Energy Drinks

Energy drinks are often packaged in PET bottles for their portability and visibility on store shelves. The PET Beverage Juice Blow Molding Machine can produce bottles with unique shapes and designs that are characteristic of energy drink brands. The ability to produce bottles with precise dimensions ensures that the bottles can be easily filled and capped, maintaining the integrity of the energy drink formula.

| Main machine (blower + oven ) |

Item |

ZP-2L-4 |

| Product Spec |

Max. product volume (L/cav) |

2L |

| Max. product neck size (mm) |

100 |

| Max. product diameter (mm) |

180 |

| Max. product height (mm) |

300 |

| Cavities |

4 |

| Blow molding part |

Die force (KN) |

100 |

| Die stroke (mm) |

270 |

| Max. mould size (mm) |

390*345 |

| Mould thickness |

Adjustable |

| Mould spacing (mm) |

Adjustable |

| Max. pulling stroke (mm) |

400 |

| Operation pressure (Mpa) |

0.8-1.0 |

| Operation air pressure consumption (1tr/min) |

200 |

| Blow pressure (Mpa) |

1.2-2.8 |

| Blow air pressure consumption (1tr/min) |

300 |

| Output (pcs/h) |

2600-2800 (500ml bottle) |

| Machine size (LxWxH)(m) |

1.46*0.58*1.8 |

| Machine weight (KG) |

650 |

| Oven |

Temperature grade (rate) |

8 |

| Heating time (S) |

90-200 |

| Voltage (V) |

220 or as your request |

| Frequency (HZ) |

50/60 |

| Total power (KW) |

16 |

| Oven Size (LxWxH) |

1.35*0.55*1.15 |

| Oven weight (KG) |

300 |

Q Series PET Bottle Blowing Machine Description

PET linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

Semi-auto blow molding machine

Semi-automatic bottle blowing machine is controlled by microcomputer,control the technical parameters more accurately.PET bottle blowing machine is simple and safe to operate.It only requires one person and does not require special training. PET blow molding machine is suitable for blow molding of plastic packaging bottles such as carbonated beverage bottles, mineral water bottles, hot filling bottles and cosmetic bottles. It is suitable for the production of small beverage companies and daily chemical product companies.

Infrared lamp heating

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; heating lamp,reflector width and height can be adjusted to suit preform heating of different structure,with automatic temperature-removal device to ensure the constant temperature of oven.

Specially designed high rigidity composite mold structure

Specially designed high rigidity composite mold structure, wide applicability, suitable for various types of mold thickness, easy to adjust and save energy, less air demand, precision polished spindle, equipped with photoelectric sensor, low noise,rapid response, long working hours , stable performance,ensure stable operation.