Revolutionizing Beverage and Juice Packaging: The Power of PET Automatic Beverage Juice Blow Molding Machines

May.23.2025

In the dynamic and highly competitive realm of the beverage and juice packaging industry, innovation and efficiency are the keys to success. At the forefront of this innovation lies the PET Automatic Beverage Juice Blow Molding Machine, a cutting - edge piece of equipment that has transformed the way PET bottles are produced. With its advanced technology, high - speed operation, and unparalleled precision, this machine has become an indispensable asset for manufacturers aiming to meet the ever - growing demands of the market while maintaining the highest standards of quality.

1. The Evolution of PET Bottle Production

PET (Polyethylene Terephthalate) has long been the material of choice for packaging beverages and juices due to its exceptional properties. It is lightweight, shatter - resistant, highly transparent, and offers excellent barrier protection against oxygen, moisture, and other contaminants. The production of PET bottles has evolved significantly over the years, with the advent of automatic blow molding machines representing a major leap forward in terms of productivity and quality.

The traditional semi - automatic blow molding machines, while effective, had limitations in terms of production speed and consistency. They required significant manual intervention, which not only increased the risk of human error but also limited the overall output. In contrast, PET automatic beverage juice blow molding machines are designed to operate with minimal human involvement, leveraging advanced automation technologies to streamline the production process and deliver superior results.

2. Key Features and Advantages of PET Automatic Beverage Juice Blow Molding Machines

2.1 Unmatched Production Speed

One of the most significant advantages of automatic blow molding machines is their ability to produce PET bottles at an incredibly high speed. These machines are equipped with state - of - the - art servo - driven systems and high - performance motors that enable rapid cycle times. For example, some advanced models can produce up to several thousand bottles per hour, significantly increasing the production capacity of manufacturers. This high - speed production is crucial for meeting the large - scale demands of the beverage and juice industries, where products need to be packaged and distributed quickly to reach consumers.

2.2 Precision and Consistency

Precision is the hallmark of PET automatic blow molding machines. They utilize advanced sensors and control systems to monitor and adjust every aspect of the production process with utmost accuracy. The temperature control during preform heating is so precise that it ensures each preform is heated to the exact temperature required for optimal blowing, resulting in bottles with consistent wall thickness and uniform shape. This level of precision not only enhances the structural integrity of the bottles but also improves their aesthetic appeal, making them more attractive to consumers.

2.3 Advanced Automation and Intelligent Control

Modern PET automatic blow molding machines are equipped with intelligent control systems that can be programmed to handle a wide variety of bottle designs and production requirements. These systems use advanced algorithms and machine learning technologies to optimize the production process, adjusting parameters such as blowing pressure, cooling time, and mold movement in real - time. For instance, if there is a change in the raw material properties or a shift in the production environment, the machine's control system can automatically make the necessary adjustments to maintain consistent quality. This level of automation not only reduces the need for manual intervention but also minimizes the risk of production errors.

2.4 Versatility in Bottle Design

PET automatic blow molding machines offer unparalleled versatility in bottle design. Manufacturers can produce bottles of various shapes, sizes, and neck finishes, from standard cylindrical bottles to complex, custom - shaped containers. The machines can easily accommodate different mold sizes and types, allowing for quick and seamless changeovers between different bottle designs. This versatility enables beverage and juice companies to differentiate their products on the market, creating unique packaging that stands out on store shelves and attracts consumers.

2.5 Energy - Efficiency and Sustainability

In an era where environmental sustainability is a top priority, PET automatic blow molding machines are designed with energy - efficiency in mind. They incorporate advanced energy - saving technologies, such as regenerative heating systems and efficient cooling mechanisms, to minimize energy consumption. Additionally, the use of PET as a packaging material is highly sustainable, as it is 100% recyclable. These machines can also be integrated with recycling systems, allowing manufacturers to reuse PET waste and reduce their environmental impact.

3.1 Preform Loading and Orientation

The production process begins with the automatic loading of PET preforms into the machine. The preforms are carefully oriented and fed into the heating section using a high - speed conveyor system. Some advanced machines are equipped with vision systems that can detect any defects or misalignments in the preforms, ensuring only high - quality preforms are used in the production process.

3.2 Precision Heating

Once the preforms are loaded, they enter the heating chamber, which is equipped with advanced infrared heating elements. The heating process is precisely controlled to ensure that the preforms are heated evenly and to the optimal temperature. The preforms are rotated continuously during heating to ensure uniform heat distribution, which is essential for achieving consistent bottle quality. The temperature and heating time can be adjusted according to the specific requirements of the bottle design and the type of PET material used.

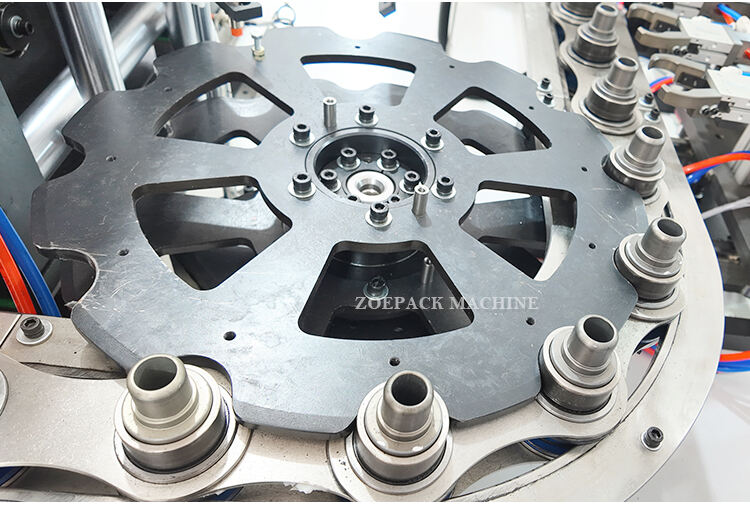

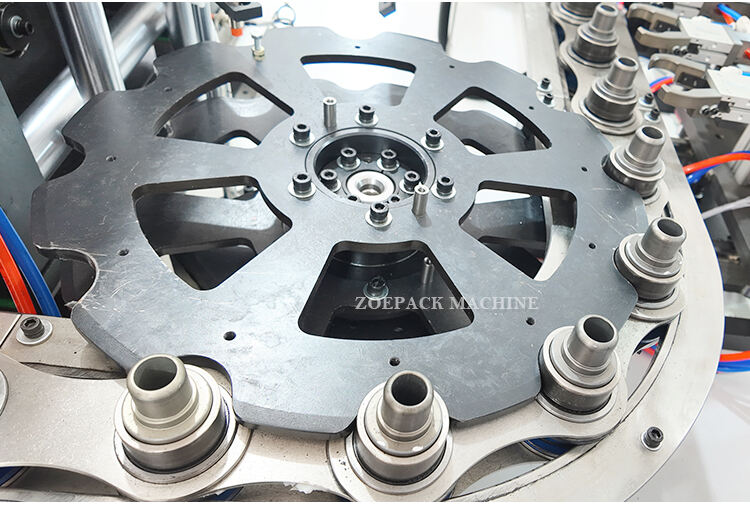

3.3 Blowing and Shaping

After the preforms are heated to the appropriate temperature, they are transferred to the blowing station. Here, the preform is placed inside a mold cavity, and high - pressure compressed air is injected into the preform, causing it to expand and take the shape of the mold. The blowing process is carefully controlled, with parameters such as air pressure, blowing time, and mold temperature optimized to achieve the desired bottle shape and wall thickness. The use of advanced servo - driven systems ensures smooth and precise mold movement, resulting in accurate and consistent bottle shaping.

3.4 Cooling and Ejection

Once the bottle is blown to the desired shape, it enters the cooling phase. The mold is equipped with an efficient cooling system, typically involving water - cooled channels, to rapidly solidify the PET material and set the bottle's shape. After the cooling process is complete, the mold opens, and the finished bottle is automatically ejected from the machine using a robotic arm or an automated ejection system. The bottles are then conveyed to the next stage of the production process, such as filling and capping.

4. Applications in the Beverage and Juice Industries

4.1 Bottled Water

In the bottled water industry, PET automatic blow molding machines are widely used to produce high - quality, lightweight bottles. The transparency of PET allows consumers to easily see the quality of the water inside, while the strength and durability of the bottles ensure that the water remains protected during transportation and storage. The high - speed production capabilities of these machines enable bottled water manufacturers to meet the large - scale demand for their products efficiently.

4.2 Fruit Juices

For fruit juice manufacturers, PET automatic blow molding machines offer the ability to produce bottles that not only protect the flavor, color, and nutritional value of the juice but also have an attractive design. The excellent barrier properties of PET prevent oxygen from entering the bottle, which helps to preserve the freshness of the juice for longer periods. The versatility in bottle design allows juice companies to create unique packaging that appeals to consumers and differentiates their products in the market.

5. Choosing the Right PET Automatic Beverage Juice Blow Molding Machine

5.1 Production Requirements

When choosing a PET automatic blow molding machine, it is crucial to consider your production requirements. This includes factors such as the volume of bottles you need to produce per day, the range of bottle sizes and shapes, and the production speed required. Select a machine that has the capacity to meet your current and future production needs, while also offering the flexibility to handle different bottle designs.

5.2 Machine Features and Specifications

Evaluate the features and specifications of different machines carefully. Look for machines that offer advanced technologies, such as precise temperature control, high - speed servo - driven systems, and intelligent control systems. Pay attention to the quality of the components used in the machine, as this will directly impact its performance and reliability. Additionally, consider the ease of maintenance and the availability of spare parts, as these factors will affect the overall cost of ownership.

5.3 Manufacturer Reputation and Support

Choose a machine from a reputable manufacturer with a proven track record in the industry. A reliable manufacturer will not only provide high - quality equipment but also offer comprehensive after - sales support, including training, technical assistance, and a readily available supply of spare parts. Reading customer reviews and testimonials can give you valuable insights into the manufacturer's reputation and the quality of their products and services.

5.4 Cost - Benefit Analysis

Finally, conduct a cost - benefit analysis to determine the most cost - effective machine for your business. Consider not only the initial purchase price of the machine but also the long - term operating costs, including energy consumption, maintenance, and repair costs. A machine that may have a higher upfront cost but offers better performance, reliability, and energy - efficiency may be a more cost - effective investment in the long run.

In conclusion, PET Automatic Beverage Juice Blow Molding Machines have revolutionized the beverage and juice packaging industry, offering a combination of high - speed production, precision, versatility, and energy - efficiency. By understanding the key features and advantages of these machines, as well as the factors to consider when choosing one, manufacturers can make an informed decision that will help them stay competitive in the market and meet the evolving needs of consumers.