Oppnå Uforutsette Effekter med Vår 4 Huler Full Automatisk Flaskeformingsmaskin

I den høyt konkurrerende domenet for plastflaskemproduksjon driver jakt på fremragende produktivitet, nøyaktighet og tilpasningsdyktighet innovasjon. Vår 4 Huler Full Automatisk Flaskeformingsmaskin kommer som en pionerendt kraft, integrerer siste teknologi, intelligent design og robust ytelse for å omdefinere grenser for hva som er mulig i flaskeproduksjon.

Smart Touch-Operasjon for Enkel Kontroll

Vår 4-hullige fullautomatiske flaskehullspressmaskin er utstyrt med en stat - av - kunsten berøringstype farge HMI-system, et revolusjonerende grensesnitt som transformerer produksjonserfaringen. Den intuitive styringspanelen fungerer som nervereset for maskinen, og tilbyr en smidig og brukervennlig drift. Den høyoppløselige fargedisplayet viser informasjon på en klar og organisert måte, slik at operatører enkelt kan få tilgang til og administrere alle aspekter av produksjonsprosessen.

Med en enkel berøring kan operatører navigere gjennom en bred vifte av funksjoner, fra å sette opp komplekse produksjonsparametere til å overvåke reeltids ytelsesmål. HMI-systemet har også intelligente varsler og advarsler, som guider operatører gjennom hver trinn av prosessen og minimerer risikoen for feil. Uansett om du er en erfaren profesjonell eller ny i flaskehulling, sikrer vår berøringsevne operasjon at du raskt kan beherske maskinen og oppnå optimale resultater.

Høy kapasitet med lynhastighet

En av de fremragende egenskapene ved vår maskin er dens imponerende produseringskapasitet og hastighet. Den kan blåse flasker opp til 10 liter i volum, og dekker en bred vifte av pakkebehov, fra småskala håndverksprodukter til storevolums kommersielle drikker. Den firekavitative designen er en spillomslag, som tillater samtidig produksjon av flere flasker og øker utgangsmengden betydelig.

Med en maksimal produsjonshastighet på 1500 flasker per time, overgår vår maskin tradisjonelle modeller, og lar deg møte stramme frister og håndtere høyvolumsordrer uten anstrengelse. Det avanserte automasjonssystemet sørger for glad i operasjon og minimerer nedetid, mens produktiviteten maksimeres. Uansett om du produserer flasker for mat- og drikkevarer, legemidler eller kosmetikk, leverer vår maskin konsekvent kvalitet på et uslagbart tempo.

Fleksibel kompatibilitet for diverse anvendelser

Vår 4-hull Full Automatisk Flaskeformingsmaskin er utformet for å være høygradig fleksibel, noe som gjør den til den ideelle valget for en bred vifte av industrier. Den er kompatibel med alle typer PET-flasker, herunder de som brukes for olje, bløtdrikker, mineralvann, vin, medisin, kosmetikk og mer. Maskinens fleksible design tillater enkelt tilpassing av flaskeformer, størrelser og veggtykkelser, noe som lar deg opprette unike og opptakne pakkingløsninger.

Rask-skift formesystemet forsterker ytterligere maskinens fleksibilitet, ved å tillate hurtig skifting mellom ulike flaskeutformingar. Dette betyr at du enkelt kan tilpasse deg til endringer i markedets krav og lansere nye produkter på et tidligere tidspunkt. Uansett om du ønsker å produsere standardformede flasker eller komplekse, tilpassede beholderdesigner, har vår maskin evnen til å gjennomføre din visjon.

Presisjonsteknikk for overleg kvalitet

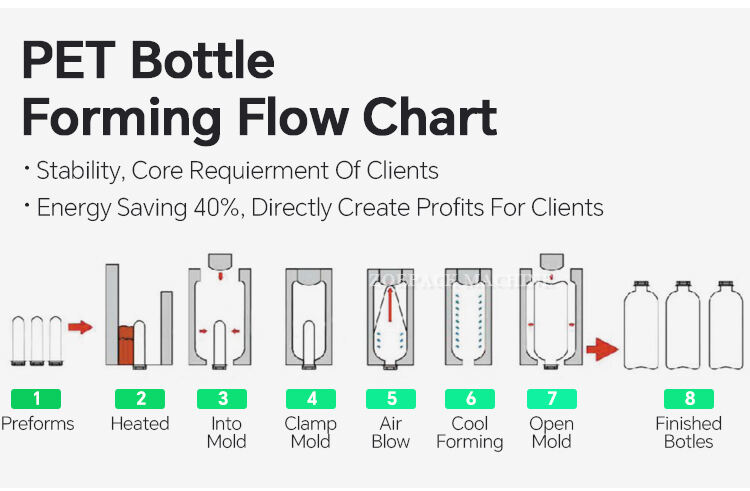

Kvalitet står i sentrum av vårt designfilosofi, og vår 4 Huler Full Automatisk Flaskeformningsmaskin er et bevis på denne engagementen. Hver eneste komponent i maskinen er nøyaktig utformet ved hjelp av den nyeste teknologien og høykvalitetsmaterialer for å sikre pålitelig og konsekvent ytelse. Det avanserte ekstrusjonssystemet oppvarmer og smelter PET-materialet jevnt, for å sikre en glad og likestilt strøm. Dette resulterer i flasker med konsistent veggtykkelse, fremragende klartet og overlegnet styrke.

Formingprosessen kontrolleres nøye for å sikre nøyaktig form og størrelse på hver flaske. Det høytrykksluftsystemet utvider plastparisonen med presisjon, og lager flasker med jevne overflater og nøyaktige dimensjoner. I tillegg er maskinen utstyrt med en serie kvalitetskontrollsensorene som overvåker produksjonsprosessen i sanntid. Hvis noen avvik oppdages, justerer maskinen automatisk parametrene for å opprettholde de høyeste kvalitetsstandardene.

Energiforbruk - effektivt og miljøvennlig

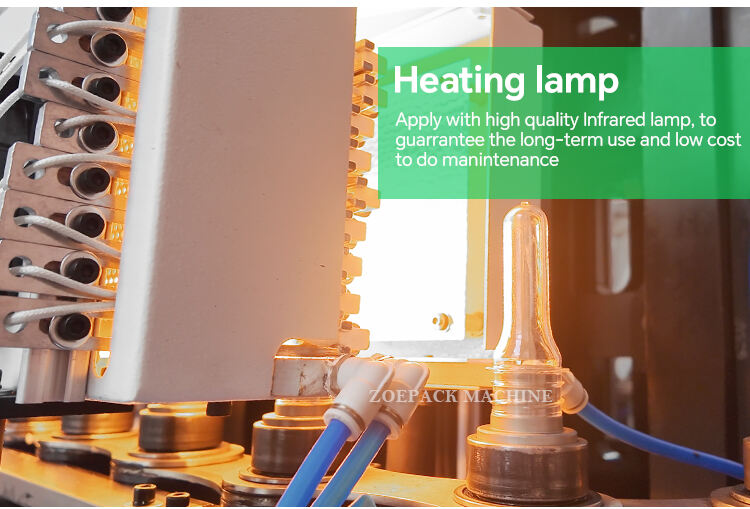

I dagens miljøbevisste verden er bærekraftighet et topprioritet. Vår 4 Huler Full Automatisk Flaskeformingsmaskin er designet med energibesparende funksjoner som ikke bare reduserer driftskostnadene, men også minimerer miljøpåvirkningen. Den intelligente varmesystemet bruker avansert temperaturkontrollteknologi for å optimere energiforbruket, og sørger for at PET-materialet varmes opp til den optimale temperaturen uten å spille unødige mengder energi.

Det effektive kjølesystemet er også designet for å minimere energibruket, ved rask kjøling av de formede flaske og reduksjon av den totale produksjonskjeden. Ved å velge vår maskin kan du bidra til en grønnere fremtid samtidig som du nyter betydelige besparelser på dine energiregninger.

Omfattende etterforsyningsstøtte

Vi forstår at å investere i en ny produksjonsmaskin er en betydelig beslutning, og vi er engasjert i å gi våre kunder omfattende etterverkssupport. Vår gruppe av erfarna teknikere er tilgjengelig for å bistå med installasjon, opplæring og vedlikehold, for å sikre at maskinen din fungerer på toppprestasjon hele tiden.

Fra øyeblikket maskinen din ankommer ditt anlegg, vil våre ekspertner arbeide tett sammen med deg for å sikre en glad i installasjonsprosess. Vi tilbyr dyptgående opplæringsøkter for operatørerne dine, dekker alt fra grunnleggende drift til avansert feilsøking. I tillegg tilbyr vi regelmessige vedlikeholdsoppdrag for å holde maskinen i optimal tilstand, forlenger dens levetid og maksimerer produktiviteten. Vår raske kundestøtteservice er alltid klar for å håndtere eventuelle bekymringer eller problemer du har, og gir tidlige løsninger for å minimere nedetid.

I konklusjon er vår 4 Huler Full Automatisk Flasjemoldingsmaskin en revolusjonerende løsning som tilbyr usetefør effektivitet, versatilitet og kvalitet. Med sin smarte berøringsskjerm-drivne operasjon, høykapasitetsproduksjon, flersidig kompatibilitet, nøyaktig ingeniørvirksomhet, energieffektiv design og omfattende etterverkssupport, er den den ideelle valget for produsenter som ønsker å ta sin flaskeproduksjon til et nytt nivå. Kontakt oss idag for å få mer informasjon om hvordan maskinen vår kan transformere din bedrift.

1. stabil og nøyaktig kjøring på høy fart, bruker mer stabilt og avansert mikrodatamaskinbasert PLC-styringssystem.

2. produksjonsprosessen er fullstendig automatisert, med fordelen på lave investeringer, høy effektivitet, enkel drift, enkel vedlikehold og sikkerhet.

3. egnet for fleksibel produksjon av både små og store mengder og ulike flaskehullformer, bredd i anvendelsesområder, oppfyller kundenes behov.

4. manuell og automatisk operasjonsmetode, menneske-maskin-grensesnitt-kontroll.

enkel drift.

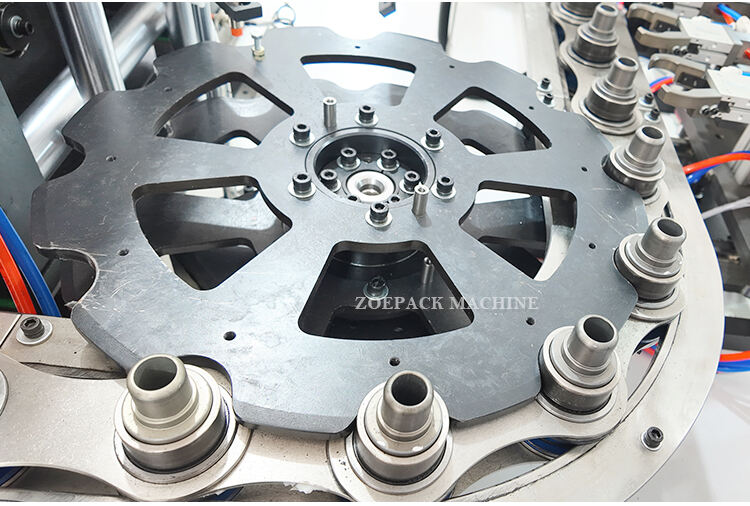

5. servodrevsystem, høy posisjonsnøyaktighet, rask fartstabilitet og god pålitelighet.

6. mindre enn 0,2% avfall for ferdigflaske.