They are cool machines that help workers of a chemical industry to package their products. Ampule sealers make the process of packaging faster and more accurate, which is why these machines are very beneficial.

ZOEPACK chemical packaging equipment are the superheroes of the chemical industry... They help transform the way companies send their products which is a much easier process. Before these machines existed, everything was packaged manually, which was a long and laborious process. To put each item in it is box or bag, to do so was tedious work. But now, thanks to these fantastic machines, workers can package quickly and accurately. Not only does this make the job easier for the employees, but it allows companies to prepare their products for sale much quicker. When employees can pack more in less time, it contributes to the smooth operation of the whole company.

They make a substantial contribution to helping the chemical industry with automated packing machines. These machines can package products on their own, with no assistance from humans. Quite nice because it reduces the chances of doing errors while packing. This means products are packaged accurately and safely meaning less error. Thanks to automated machines, businesses like ZOEPACK can efficiently and correctly package their goods. The chemical packaging machine helps them work more efficiently, and their customers are consistently happier as they get the exact products they need. To rejoice consumers who are inclined to return for additional.

A huge way packaging machines are transforming the chemical industry. They are enabling packaging in not only a quicker, but also a more convenient and more reliable way. This shift enables companies like ZOEPACK to package their products with chemical packing machine closer to what people want and need. These devices enable companies to pack more products in less time. This, in turn, means more sales, which is how companies make money. The quicker they can get products on the shelves, the better they can compete when the product is there.

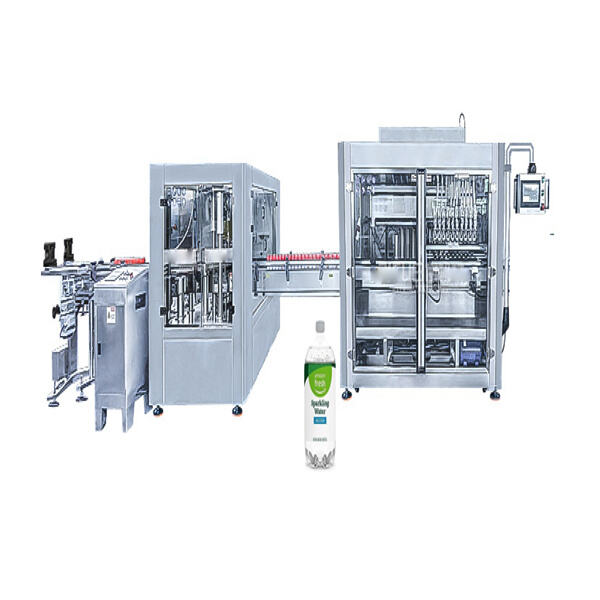

The chemical industry makes great use of packaging machines as well as chemical filling machine. All manner of product can be packaged, whether liquid, powder, or solid. This versatility of packaging machines is so important for ZOEPACK and the companies because many different products can easily pack. These machines can package anything from a tiny bottle of shampoo to a huge bag of fertilizer, and do so like a champ. Being able to package that products in different types allows companies to bring a different range of products for it is clients.

Packaging machines are undergoing continuous improvement with new technology. But rather than rest on their laurels, firms such as ZOEPACK will be constantly looking for better, more efficient ways to package things. And new tools and ideas are helping them to do this. An example to this is the packaging machinery that can now operate at a much higher speed and package more products in a shorter time. They are also improving their ability to accurately measure things so that every product is packaged to perfection. Such new technologies keep chemical companies ahead of the curve and their competitors. As new technology is developed, packaging machines are being aggressively adopted by businesses that want to succeed and grow.

Our Packaging machine for chemical industry collaborates closely with our clients to design unique bottle designs that are not just functional but also reflect the br 's identity considering factors like texture material usability for an item that is aesthetically pleasing practical. Additionally we offer expert production line layout planning making detailed drawings that are adapted to your workshop's dimensions to maximize the placement of equipment as well as workstations storage areas which will improve efficiency workflow. Additionally we provide packaging guidance analyzing the best caps bottles labels based on the product's type market dem s. ensures consistency aesthetic appeal helps reinforce the br 's image. To aid in your financial success we aid in calculating profit points by taking account local costs such as production materials as well as distribution. Our team of experts utilizes sophisticated financial models to provide insight the strategies for pricing profit margins helping the business to make better decisions optimize your business strategy for sustainable growth.

Our engineers provide overseas installation and commissioning services to ensure proper setup and seamless operation Our experienced engineers can provide installation and commissioning services in foreign countries to assure smooth operation If our customers encounter any concerns we provide 24/7 online support to help resolve them promptly Our staff will provide complete instruction and assistance to all customers who visit our facility Our commitment to assist our customers demonstrates our commitment to building strong Packaging machine for chemical industry and to ensuring their success.

Prior to shipping, all of our equipment undergoes rigorous testing to ensure that there are no quality issues and to meet our strict standards prior to reaching the facility of our customer. We provide installation and commissioning assistance through our skilled engineers to ensure correct setup and smooth operation. If customers experience issues our online support is available to help with troubleshooting and real-time communication via video calls, helping to fix issues quickly and reduce downtime. We also suggest that clients visit our factory for hands-on training in the operation of equipment, where our staff provides comprehensive guidance and support free of charge. This commitment to customer support is a Packaging machine for chemical industry to our commitment to establishing strong relationships and guaranteeing our clients' satisfaction.

Comparatively to the majority of factories, our equipment has a filling speed that's nearly 15% quicker, drastically improving Packaging machine for chemical industry in production and throughput. We adhere to strict standards for the dimensions and specifications of every component, which ensures that our equipment delivers superior precision and stability. Our dedication to quality is evident in the equipment we employ. We prefer well-known brands like Alfa Laval and SMC. They are recognized for their reliability and efficiency in the industry. While many factories have flow rates of up to 15m/sec our design focuses on long-term durability and efficiency, leading to lower operating costs and less maintenance needs. Our filling machine has a long-standing track record, with some units still in use for over 10 years. This proves the longevity of our equipment but additionally demonstrates our commitment to provide reliable solutions that meet the requirements of our customers in a highly competitive market.