Chemical packaging equipment are very important while manufacturing products. This equipment helps ensure safe and effective chemical packaging for use in various products. ZOEPACK knows how to leverage the best machineries to pack chemicals. They specialize in this space and are focused on quality product delivery.

ZOEPACK continuously seeks methods to improve their chemical filling as well as chemical packaging equipment. They know that technology is constantly evolving and they prefer to embrace the best processes available to encourage their success. New improvements that they have brought in is the use of automated systems. These automated machines are capable of doing most of the work on their own and therefore workers do not have to do every step by hand. That makes it a lot easier and quicker for the workers to package chemicals. ZOEPACK has had these automated systems in place since, and the speed and efficiency with which they have been able to package their chemicals have seen a massive improvement.

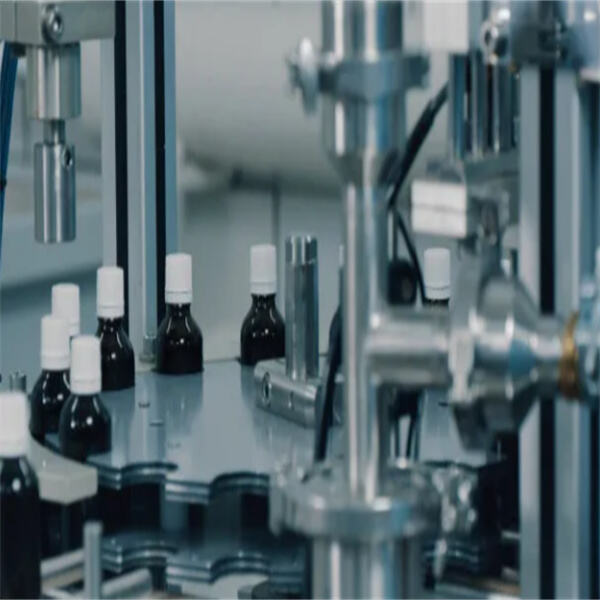

ZOEPACK Packaging of Chemicals

This is how we do it, which means that they focus extra on ensuring that all the machines are functioning correctly and are safe to use. They also make sure that the workers are trained on how to safely and effectively use the machines. ZOEPACK is very serious about safety. ZOEPACK also regularly cleans the machines to ensure hygiene. Maintaining the machines properly by cleaning them is crucial as dirt in the machines can be problematic and affect the way they work. So in conclusion if ZOEPACK sticks to these rules it will have a much more efficient aeration of its chemical filling machine and chemical packaging machines.

Working with the right type of chemical packaging equipment along with chemical filling equipment can truly enhance production processes. And ZOEPACK knows that all too well. When they have good machines working at a faster pace, they can package chemicals in less time. This allows them to develop and deliver additional products to their customers more quickly. Since the time best chemical packaging equipment was adopted, ZOEPACK has experienced a massive jump in their production. They have their business running smoothly and with a demand from customers

ZOEPACK has persistent safety conscience about product packages and only applies new technologies and the latest innovations in the field of chemicals packaging. If your products are not packaged properly for safety and quality reasons, they will refuse to accept them. One of ZOEPACK's cool technologies is known as RFID tagging. However, with this technology, they can always know the location of all their products, which makes it a great help in this aspect. And with new technologies, including RFID tagging system, ZOEPACK can keep their chemicals secure while also keeping them accessible. This sort of added layer makes it easier to respond quickly to customer orders.

ZOEPACK knows, however, that different chemicals require different packaging and chemical liquid filling machine. And why they have so many different options when it comes to packaging equipment. They know that the stuff they need to package might be liquids, powders, or gels, and it takes specific machines to do the job. With so many types of your equipment, ZOEPACK can adapt to whatever packaging challenge they are up against. They can cater to multiple customers and cater to any chemical packaging need with this flexibility.

Our design team of experts works closely with clients to create unique bottle designs that fulfill functional needs but also match with the brand's branding. We consider factors such as the material, shape and usability in order to design a product that is both visually appealing and practical. We also provide professional layout and layout design services for production lines, creating detailed diagrams tailored to the size of your workshop's space to maximize equipment placement, workstations, and storage areas, thereby improving efficiency and workflow. Additionally, we provide packaging advice, analyzing suitable caps, bottles, and labels to match the type of product you are selling and needs of the market. This helps ensure compatibility and visual appeal and helps reinforce the brand's image. We can help you calculate profit margins by analyzing your Chemical packaging equipment, including production, material, and distribution. Our team utilizes detailed financial models to give you insight into the pricing strategy, margins of profit, and the business plan. This helps you make informed decisions and to optimize your overall strategy for sustainable growth.

Our engineers offer Chemical packaging equipment and commissioning to ensure the proper setup and efficient operation. We offer overseas installation and commissioning services through our skilled engineers to ensure correct setup and seamless operation. If customers encounter issues, we provide online support for real-time communication and troubleshooting via video calls, helping resolve issues swiftly and minimizing downtime. We also suggest that clients visit our facility for hands-on training in equipment operation, where our experts provide comprehensive guidance and support at no cost. Our dedication to customer service emphasizes our desire to build solid relationships and ensuring the success of our customers.

Our engineers provide overseas installation and Chemical packaging equipment services to ensure a proper setup and efficient operation. Our experienced engineers can provide installation and commissioning services in foreign countries to ensure smooth operation. If clients encounter problems, we provide online assistance to resolve them promptly. We also recommend that customers visit our factory for hands-on training in equipment operation, where our team provides complete assistance and guidance for no cost. This commitment to customer support underscores our dedication to building strong relationships, and to ensuring our clients' satisfaction.

Our equipment can fill up to 15% faster than many factories. This enhances the efficiency of production and productivity. Our equipment is built to offer high accuracy and Chemical packaging equipment. We adhere to the strictest standards in terms of the specifications and sizes. Our commitment to quality can be seen in our choice of components that we use from well-known brands such as Alfa Laval, SMC, DANFOSS and Schneider that are known for their dependability and efficiency in the industry. Our water treatment equipment is made to last with the capacity of 8m/sec which allows it to function efficiently for extended periods of time. While many factories have flow rates of up to 15m/sec our system's design prioritizes longevity and efficiency, leading to lower operating costs and less maintenance requirements. The filling machine we offer is also an tested and proven product which is why many of them are in use after more than 10 years. This longevity not only demonstrates the longevity of our equipment but further demonstrates our commitment to providing solutions that meet the needs of our clients in a highly competitive marketplace.