ZOE PACK

Semi Automatic PET Bottle Blow Molding Machine

1. Diverse Applications in the Beverage and Juice Industry

1.1 Innovation in Bottled Juice

Semi-automatic PET blow molding machines have revolutionized the bottled juice industry. With their ability to produce bottles of various shapes and sizes, juice manufacturers can create unique and eye-catching packaging that stands out on store shelves. From sleek and slim single-serve juice bottles to large family-size juice bottles, these machines can turn any design idea into reality. PET's excellent barrier properties ensure that juices remain fresh and delicious, retaining their nutritional value and taste for a longer period of time.

1.2 Bottled Water Solutions

Semi-automatic machines play a vital role in the bottled water market, which focuses on cost-effectiveness and convenience. They are able to produce lightweight, durable PET bottles that are easy to transport and handle. The consistent quality of the bottles produced by these machines ensures that the water remains pure and free of contaminants, meeting the most stringent hygiene standards. In addition, the ability to customize bottle designs allows water brands to stand out and create a strong brand image.

1.3 Carbonated and Energy Drink Packaging

For carbonated and energy drinks that require bottles with high strength and gas barrier properties, semi-automatic PET blow molding machines are up to the task. Precise control of the blowing process produces bottles with the necessary wall thickness and structural integrity to withstand the internal pressures created by carbonation or the unique formulations of energy drinks. In addition, these machines can produce bottles with innovative designs, such as ergonomic shapes for easier gripping or unique labeling areas, which enhance the overall consumer experience.

2. Choosing the Ideal Semi-Automatic PET Blow Molding Machine

2.1 Production Capacity Considerations

When choosing a semi-automatic PET bottle blow molding machine, it is critical to evaluate your production capacity needs. Factors to consider include the number of bottles you need to produce per day, week, or month, as well as any seasonal demand fluctuations. Choose a machine that can easily meet your current production needs while accommodating future growth.

2.2 Bottle Design Flexibility

If your business offers a wide variety of beverage and juice products in a variety of bottle designs, look for a machine that offers maximum flexibility. Make sure the machine can handle different sizes and types of molds and supports a wide range of blowing parameters to achieve the desired bottle shape and thickness. A machine with a user-friendly mold changing system also makes it easier to switch between different bottle shapes, reducing production downtime.

2.3 Manufacturer Reputation and Support

Working with a reputable manufacturer is essential to the success of your PET bottle production. Research the manufacturer's track record in the industry, read customer reviews and testimonials, and inquire about their after-sales support services. A reliable manufacturer will provide comprehensive training for your operators, provide timely technical support if any problems arise, and provide a steady supply of high-quality spare parts.

2.4 Total Cost of Ownership

Don't just focus on the initial purchase price of the machine; consider the total cost of ownership over its entire life cycle. This includes factors such as energy consumption, maintenance costs, repair expenses, and spare parts costs. A machine with lower long-term operating costs, even if it costs slightly more upfront, may be a more cost-effective investment in the long run.

All in all, a semi-automatic PET beverage juice bottle blow molding machine is a great asset to the beverage and juice packaging industry. Its unique manual controls, cost-effectiveness, high-quality production and user-friendly features make it an excellent choice for manufacturers of all sizes. By carefully evaluating your production needs and selecting the right machine, you can realize the full potential of these exceptional machines and take your beverage and juice packaging to new heights.

| Main machine (blower + oven ) | Item | ZP-2L-4 |

| Product Spec | Max. product volume (L/cav) | 2L |

| Max. product neck size (mm) | 100 | |

| Max. product diameter (mm) | 180 | |

| Max. product height (mm) | 300 | |

| Cavities | 4 | |

| Blow molding part | Die force (KN) | 100 |

| Die stroke (mm) | 270 | |

| Max. mould size (mm) | 390*345 | |

| Mould thickness | Adjustable | |

| Mould spacing (mm) | Adjustable | |

| Max. pulling stroke (mm) | 400 | |

| Operation pressure (Mpa) | 0.8-1.0 | |

| Operation air pressure consumption (1tr/min) | 200 | |

| Blow pressure (Mpa) | 1.2-2.8 | |

| Blow air pressure consumption (1tr/min) | 300 | |

| Output (pcs/h) | 2600-2800 (500ml bottle) | |

| Machine size (LxWxH)(m) | 1.46*0.58*1.8 | |

| Machine weight (KG) | 650 | |

| Oven | Temperature grade (rate) | 8 |

| Heating time (S) | 90-200 | |

| Voltage (V) | 220 or as your request | |

| Frequency (HZ) | 50/60 | |

| Total power (KW) | 16 | |

| Oven Size (LxWxH) | 1.35*0.55*1.15 | |

| Oven weight (KG) | 300 |

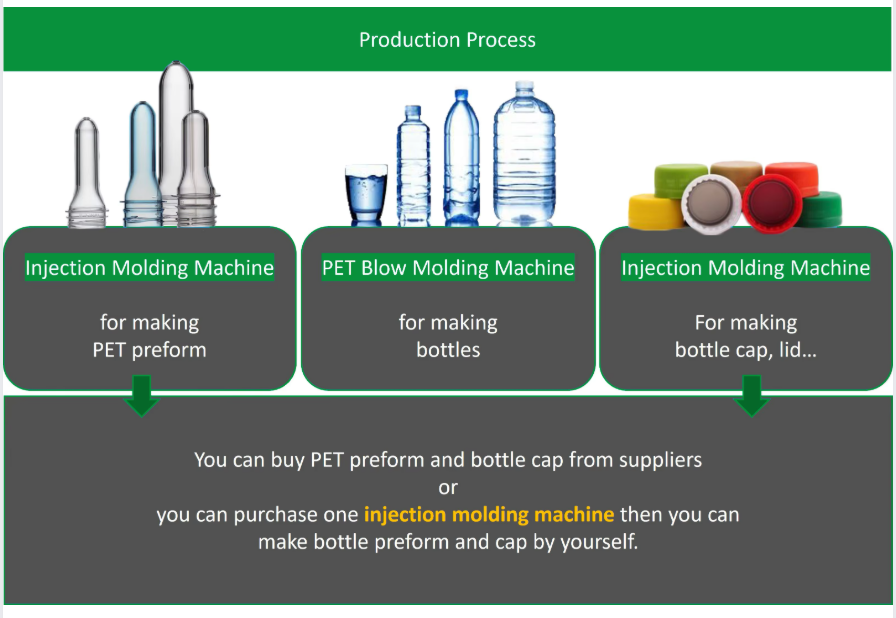

Q Series PET Bottle Blowing Machine Description

PET linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

Semi-auto blow molding machine

Semi-automatic bottle blowing machine is controlled by microcomputer,control the technical parameters more accurately.PET bottle blowing machine is simple and safe to operate.It only requires one person and does not require special training. PET blow molding machine is suitable for blow molding of plastic packaging bottles such as carbonated beverage bottles, mineral water bottles, hot filling bottles and cosmetic bottles. It is suitable for the production of small beverage companies and daily chemical product companies.

Infrared lamp heating

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; heating lamp,reflector width and height can be adjusted to suit preform heating of different structure,with automatic temperature-removal device to ensure the constant temperature of oven.

Specially designed high rigidity composite mold structure

Specially designed high rigidity composite mold structure, wide applicability, suitable for various types of mold thickness, easy to adjust and save energy, less air demand, precision polished spindle, equipped with photoelectric sensor, low noise,rapid response, long working hours , stable performance,ensure stable operation.