|

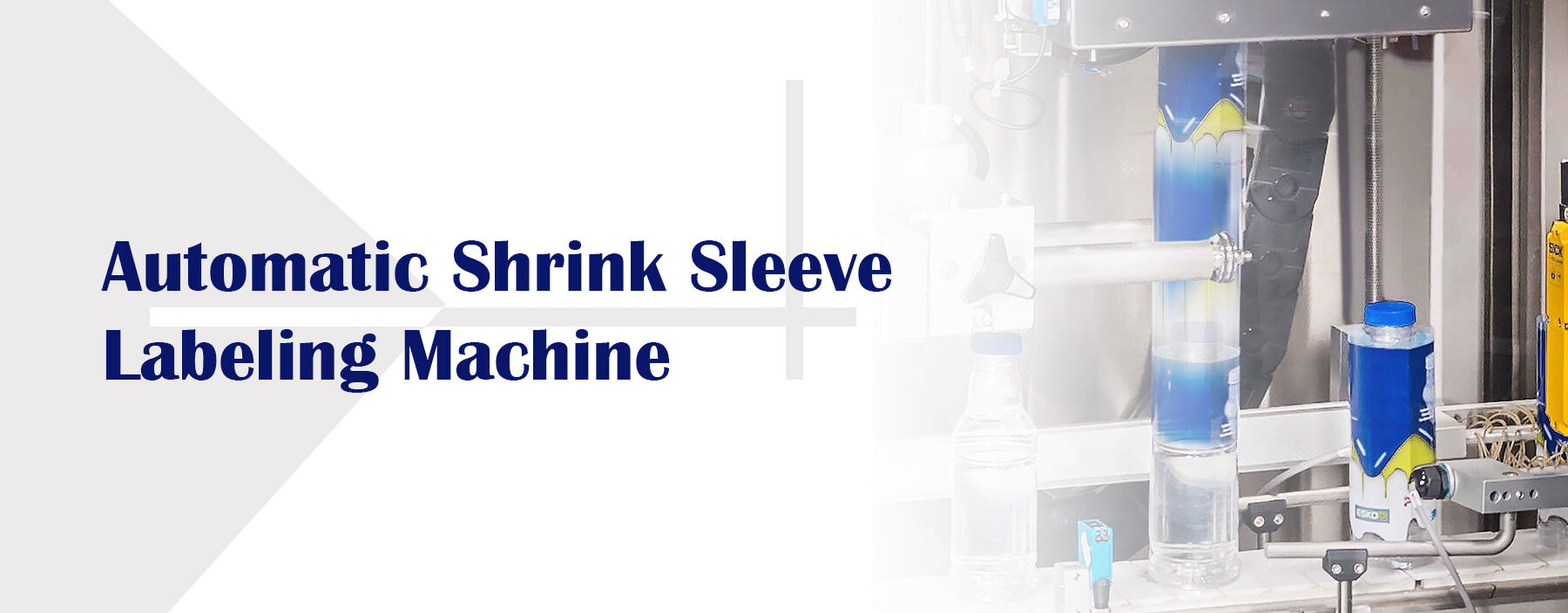

Automatic Shrink Sleeve Labeling Machine

|

||||

|

ZP-150

|

ZP-250

|

ZP-300

|

ZP-400

|

|

|

Input Power

|

2.5 KW

|

3.0 KW

|

4.0 KW

|

4.0 KW

|

|

Input Voliage

|

∮3380/220 VAC

|

∮3380/220 VAC

|

∮3380/220 VAC

|

∮3380/220 VAC

|

|

Production Etticiency

|

150 bottles / min

|

250 bottles / min

|

300 bottles / min

|

400 bottles / min

|

|

Size of Host Machine

|

2100L*850W*2000H

|

2100L*1100W*2000H

|

2600L*1100W*2200H

|

2600L*1100W*2200H

|

|

Bottle diameter

|

28 mm~120 mm

|

28 mm~120 mm

|

28 mm~120 mm

|

28 mm~120 mm

|

|

Length of Label

|

30 mm~250 mm

|

30 mm~250 mm

|

30 mm~250 mm

|

30 mm~250 mm

|

|

Thickness of Label

|

0.03 mm—0.13 mm

|

0.03 mm—0.13 mm

|

0.03 mm—0.13 mm

|

0.03 mm—0.13 mm

|

|

Paper tube diameter

|

5”—10(Free adjustment)

|

5”—10(Free adjustment)

|

5”—10(Free adjustment)

|

5”—10(Free adjustment)

|

|

Automatic Double Heads Shrink Sleeve Labeling Machine

|

|

|

Input Power

|

6KW

|

|

Input Voltage

|

∮3380 / 220 VAC

|

|

Production Etticiency

|

2*150 bottles / min

|

|

Size of Host Machine

|

3200Lx 1200Wx 2070H

|

|

Bottle Diameter

|

28 mm ~ 125 mm

|

|

Length of Label

|

30 mm ~250 mm

|

|

Thickness of Label

|

0.03 mm — 0.13 mm

|

|

Paper Tube Diameter

|

5” — 10(Free adjustment)

|

|

FAQ

|

|

Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's ZOE PACK's advantage? ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support! |

ZOEPACK

ZOEPACK Automatic Plastic Glass Bottle Aluminum Tins Shrink Sleeve Wrapping Labeling Machine with Steam Tunnel is a versatile and efficient packaging solution that is ideal for modern businesses. This innovative product is designed to streamline packaging processes and boost efficiency, while ensuring high-quality labeling and packaging results.

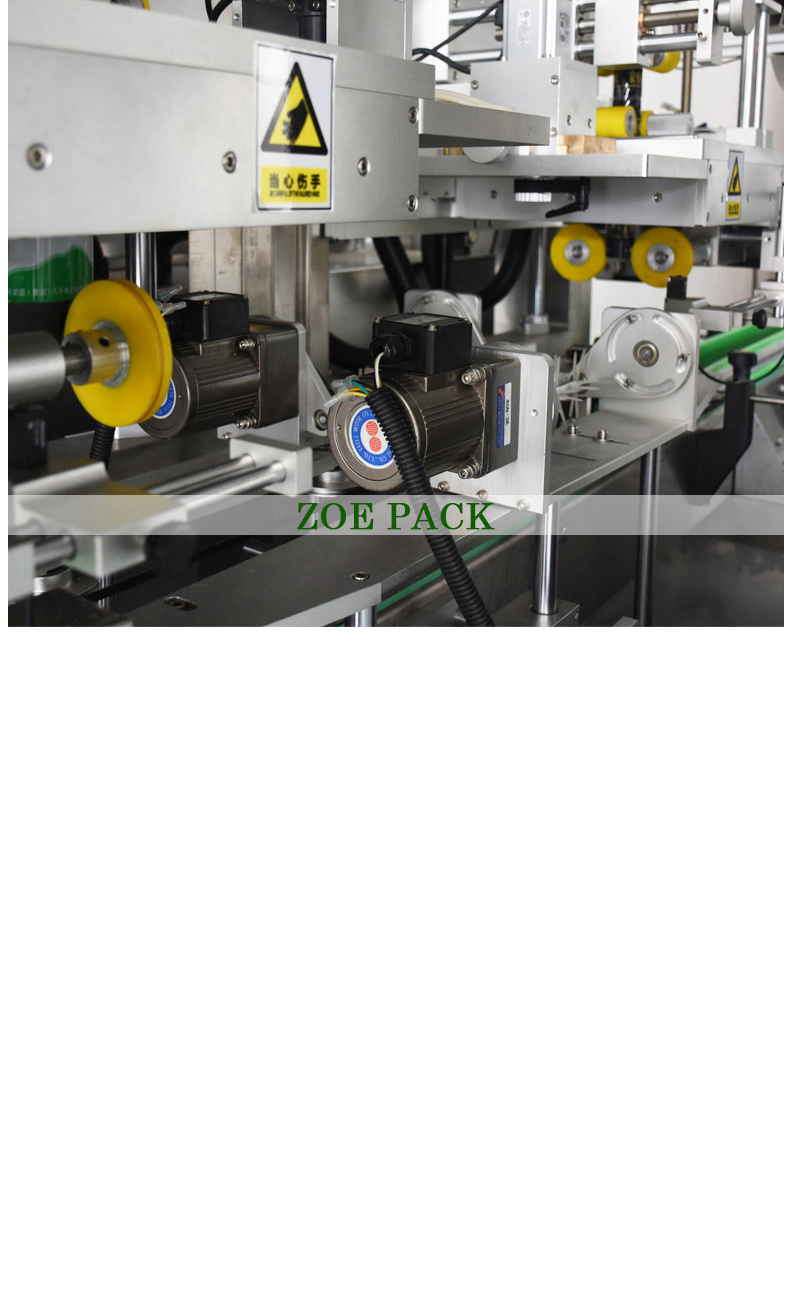

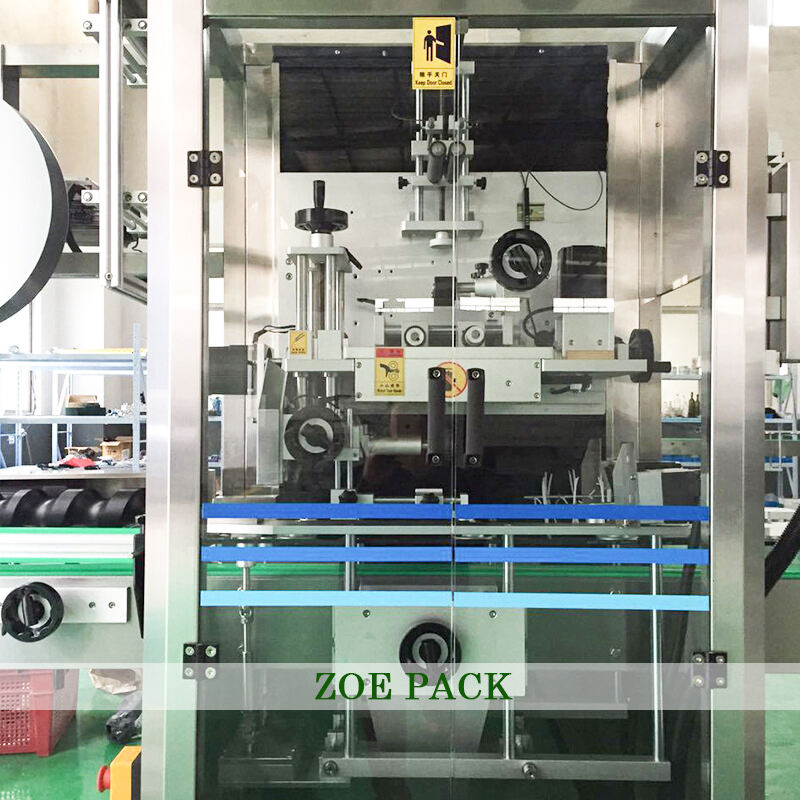

Features a compact design that saves workspace is valuable without compromising on functionality. The machine was created to meet the requirements of organizations of most sizes, also it is personalized to match packaging is unique.

Many thanks to its automatic procedure, the ZOEPACK Automatic Shrink Sleeve Wrapping Labeling Machine is easy to utilize and requires intervention is minimal operators. The device is equipped with user-friendly touch screen controls that enable staff to monitor and program operations with ease.

Able to handle a wide range of packaging materials, including plastic, cup, and aluminum tins. The machine utilizes a vapor tunnel to make certain that packaging materials are ready for labeling and shrink wrapping. The steam tunnel provides heat consistently ensuring that packaging materials are pliable and simple to utilize.

Built to minimize waste, because of its accuracy labeling and shrink capabilities that are wrapping. This results in price savings for companies, also as reduced impact is environmental.

The ZOEPACK Automatic Shrink Sleeve Wrapping Labeling Machine can be built to final in addition to its impressive performance. Made from durable materials and featuring components that are top-quality, this machine is made to stand up to the needs of modern packaging environments. Which means that businesses can depend on it to provide results that are consistent day in and day out.

Why wait? Invest in the ZOEPACK Automatic Shrink Sleeve Wrapping Labeling Machine today and discover what it can do for your businesses.