PET Preform Injection Molding Machine

The market demand for PET preform injection - blow molding machines is affected by multiple factors, and the industry competition pattern also shows certain characteristics.

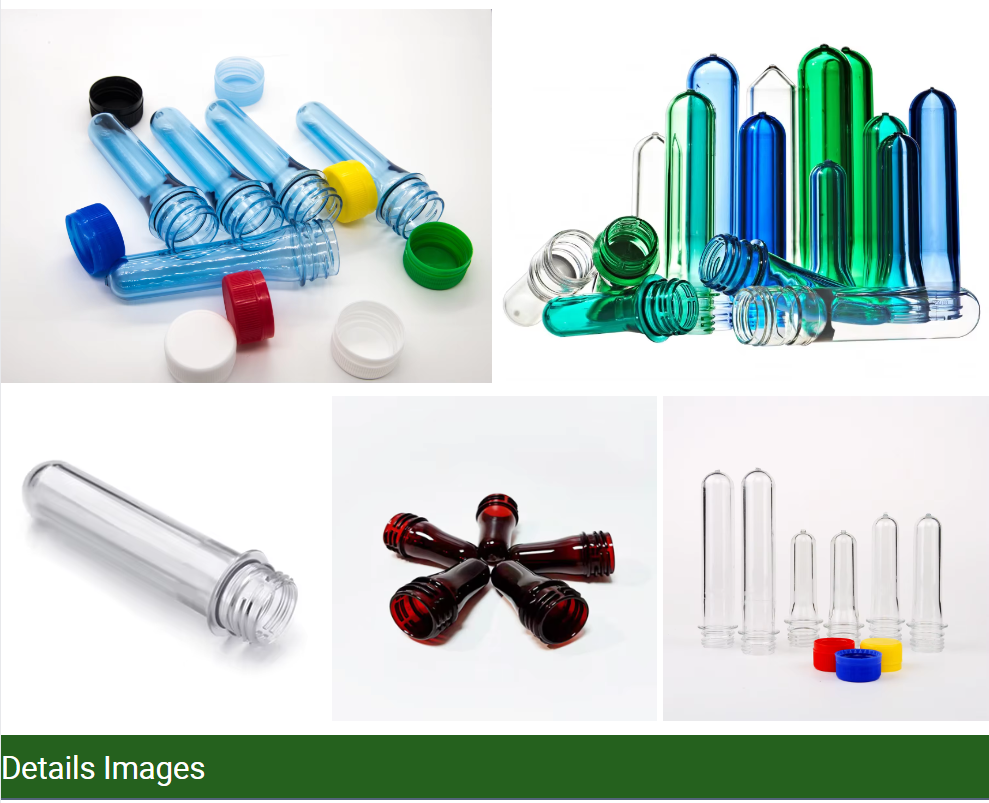

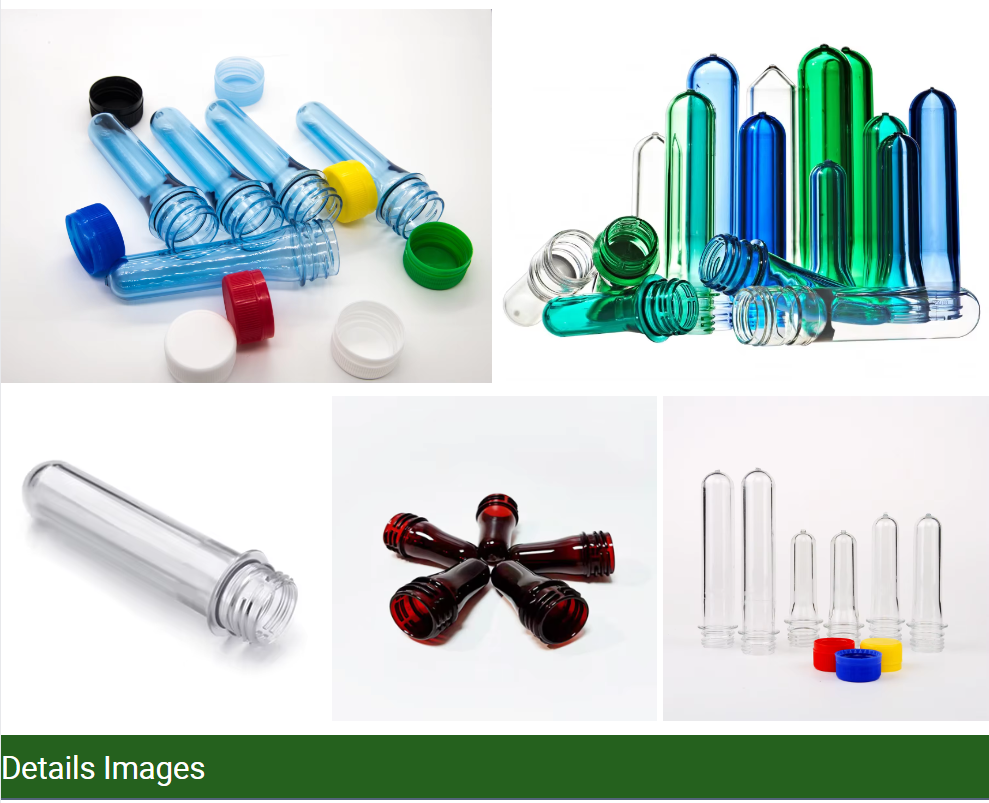

In terms of market demand, with the growth of the global population and consumption upgrading, the demand for PET bottles continues to increase. The beverage industry is the largest consumer market for PET bottles, and many categories such as mineral water, fruit juice, tea beverages, and carbonated beverages widely use PET bottles for packaging. In addition, the demand for PET bottles and other PET containers in the food, cosmetics, and pharmaceutical industries is also on the rise. For example, in the food industry, more and more sauce, edible oil and other products are beginning to use PET bottles for packaging because PET has good barrier properties and can maintain the freshness and quality of products.

In emerging markets, with the development of the economy and the acceleration of urbanization, the demand for PET bottles is growing more rapidly. Consumers in these areas have increasing requirements for the convenience, aesthetics, and safety of packaged products, which promotes the market demand for PET preform injection - blow molding machines. At the same time, the booming development of the e - commerce industry has also driven the demand for PET packaging because PET bottles have good impact resistance and stability during transportation, which are suitable for packaging e - commerce products.

From the perspective of the industry competition pattern, the global PET preform injection - blow molding machine market is highly competitive. In the high - end market, it is mainly dominated by some well - known enterprises in Europe, America, and Japan. These enterprises have advanced technology, high - quality equipment, and a perfect after - sales service system. Their equipment usually has higher production efficiency, more precise forming accuracy, and more advanced automation functions, and the prices are relatively high.

In the middle - and low - end market, enterprises in some emerging Asian economies, such as China and India, are gradually emerging. These enterprises are continuously introducing technology and improving their independent R & D capabilities to produce cost - effective PET preform injection - blow molding machines. While meeting domestic market demands, they have also begun to export equipment to other developing countries. In this market, price competition is relatively fierce, and enterprises often improve their competitiveness by reducing costs and increasing production efficiency.

In order to stand out in the competition, both high - end and middle - low - end enterprises are continuously increasing their R & D investment. On the one hand, it is to improve the performance of the equipment, such as developing new injection and blow - molding technologies and improving energy efficiency; on the other hand, it is to meet the increasingly diverse needs of customers, for example, providing customized equipment and services, and designing and producing specific PET preform injection - blow molding machines according to different product requirements of customers.