4 Cavilities Full Automatic Bottle Molding Machine

1. Flexible customization to meet personalized needs

We know that every beverage and juice manufacturer has unique needs in bottle design and production. Therefore, our PET automatic blow molding machines offer a wealth of customization options. Whether your bottle shape, size, color or functional characteristics are unique, our experienced team of engineers can work with you to design and develop custom molds and production solutions.

From stylish and modern bottle shapes for high-end beverages to practical and ergonomic designs for mass-market juices, our machines can turn your vision into reality. We can also customize the surface treatment of the bottle, such as glossy, matte or texture, and add custom printed logos, labels or patterns to enhance the brand image. In addition, we also provide different types of bottlenecks and capping options to ensure compatibility with various filling and capping systems.

2. Full-service to help business development

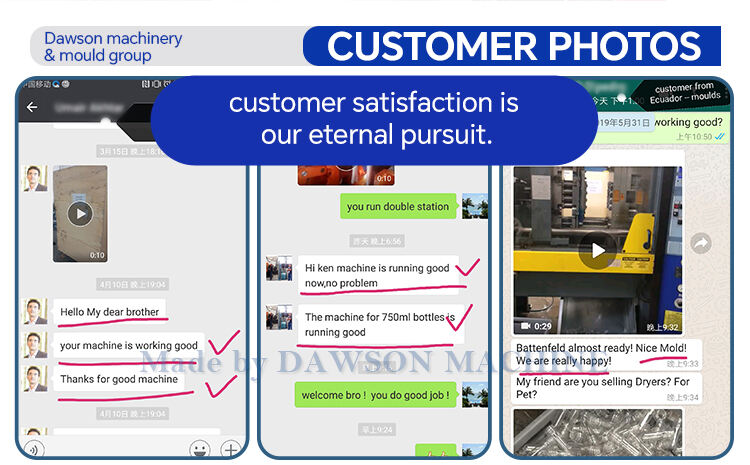

Our commitment to customer satisfaction is not limited to the sale of the machine. We provide comprehensive services to support customers throughout the life cycle of the PET automatic blow molding machine. Our team of pre-sales service experts provides in-depth technical consultation to help you choose the most suitable machine model and configuration based on production scale, product needs and budget. We also offer on-site visits to assess your production environment and provide personalized recommendations. During the installation and commissioning phases, our experienced technicians will be on site to ensure that the machine is properly installed and running smoothly. We provide a comprehensive training program for your operators and maintenance personnel, covering everything from basic machine operation to advanced troubleshooting techniques. For after-sales service, we have a global service network with service centers in major regions. Our professional technicians are on call 24/7 to respond to your inquiries and provide technical support at any time. We also provide regular maintenance and inspection services to ensure that the machine remains in optimal condition and operates reliably for a long time.

All in all, our PET automatic beverage and juice blow molding machine is a cutting-edge solution that combines advanced technology, efficient production, strict quality control, extensive customization and excellent service. It is an ideal choice for beverage and juice manufacturers who want to increase production efficiency, improve product quality and gain a competitive advantage in the market. Contact us today to learn more about how our machines can transform your beverage and juice packaging production.

| TechnicalParameters | ZPA-1L-2 | ZPA-2L-2 | ZPA-1L-4 | ZPA-2L-4 | ZPA-1L-6 | ZPA-2L-6 | |

| Cavity | 2 | 2 | 4 | 4 | 6 | 6 | |

| Host Machine Parameter |

Clamping Force | 35000 | 45000 | 48000 | 48000 | 56000 | 65000 |

| Mold Route | 90 | 110 | 90 | 125 | 90 | 125 | |

| Stretching Rod Route | 300 | 400 | 260 | 330 | 260 | 330 | |

| Boctomn llold Route | 50 | 50 | 50 | 50 | 50 | 50 | |

| Bottle Spacing | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | |

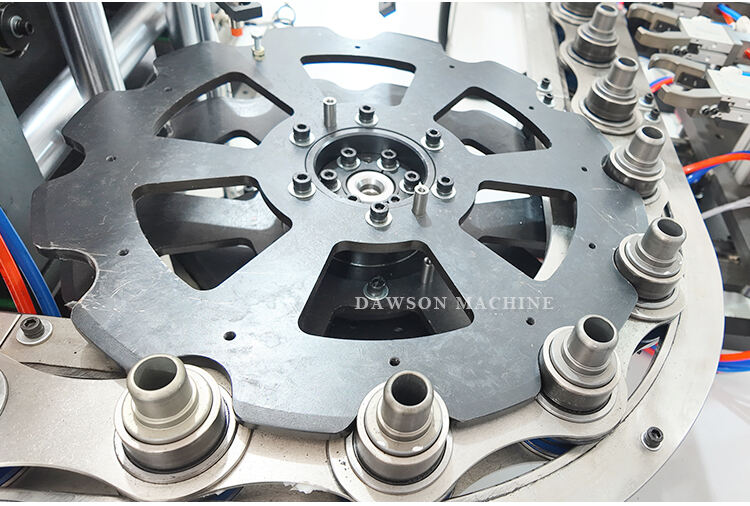

| Bottle Preform Number | 66 | 52 | 95 | 82 | 106 | 92 | |

| Prodncts Parameter |

Max Capacty | 660 | 1500 | 600 | 1500 | 600 | 1500 |

| Max Bottle Boby Height | 260 | 330 | 260 | 330 | 260 | 330 | |

| Max Bottle Body Diameter | 68 | 105 | 68 | 105 | 68 | 105 | |

| MaxBottle Preformn Height |

100 | 140 | 100 | 140 | 100 | 140 | |

| Max Bottle Mouth Diameter |

38 | 38 | 38 | 38 | 38 | 38 | |

|

Eleetrical Parameter |

Capacty | 2500 | 2000 | 4500 | 4000 | 7200 | 6000 |

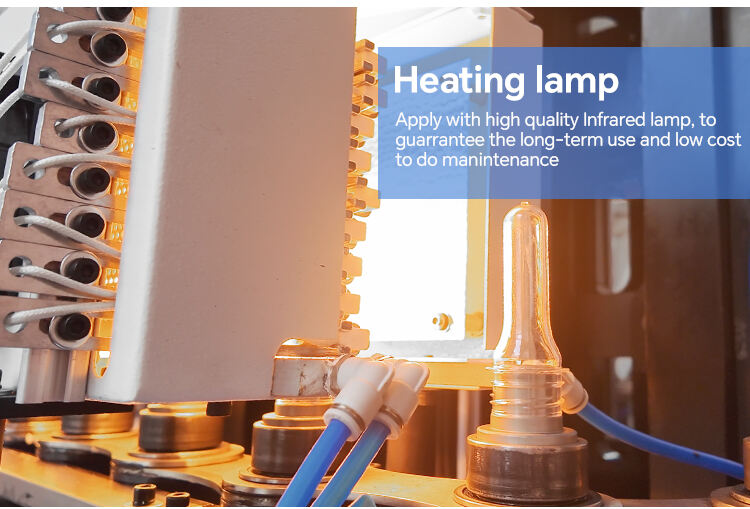

| Heating Oven Quantity | 2*2 | 4*4 | 4*4 | 5*5 | 4*4 | 5*8 | |

| Heating Lamp Quantity | 2*8 | 4*8 | 4*7 | 5*9 | 4*8 | 5*9 | |

| Heating Confguration Power | 32 | 48 | 42 | 72 | 64 | 90 | |

| Total Power Capedity | 32 | 48 | 42 | 72 | 64 | 90 | |

| Voltage | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | |

| Air source Parameter |

Worling Pressure | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| Blowing Pressure | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | |

| Air Capacitly Consumption | 2.4/30 | 2.4/30 | 3.6/30 | 3.6/30 | 5.0/30 | |

| Total Powwer | 30 | 30 | 45 | 45 | 60 | |

| Cooling Chiler Parameter | Ternperature | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 |

| Pressure | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Rated Power | 3 | 3 | 5 | 5 | 5 | |

| Dimenson | Host Machine Size | 2700*1800 | 3300*1800 | 3900*1800 | 4800*2200 | 4200*2100 |

1 .stable and accurate running at high speed,adopt more stable and advanced micro-computer PLC control system.

2. production process is fully automated, with the advantages of low investment, highefficiency,easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range ofapplications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control. simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle.

DAWSON MACHINE & MOULD GROUP

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery,injection molding machine, blow molding machine, PeT blow molding machine, injection blow moldingmachine, during the past 18 years, we always force our energy into new areas of plastic machinery,plastic packaging machinery, to update the technology, to learn advanced experience,to confirm new theory and new design, we are forming a unique competitive advantage of our owns.The machines from our company carry good quality and effective after-sales service, upon the market,customers from more than 45 countries, we provide complete solution for your plastic industrybusiness, as well as all sorts of technical support & after-sale services!

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's ZOE PACK's advantage?

ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!