4 Cavilities Full Automatic Bottle Molding Machine

1. Adaptive production system to achieve flexible manufacturing

Our PET automatic blow molding machine adopts an intelligent adaptive production system. The system uses artificial intelligence and machine learning algorithms to analyze real-time production data, including material properties, environmental conditions and equipment performance, and automatically adjust production parameters. For example, if the humidity in the production environment increases, this may affect the moisture content of the PET preform and thus affect the blowing process. The system can detect this change through the humidity sensor and adjust the heating temperature and blowing pressure accordingly to maintain consistent bottle quality.

The machine also has a self-calibration function. After a mold change or a long production run, the system can perform an automatic calibration process using a built-in reference standard. It measures the key dimensions of the newly produced bottle, such as diameter, height and wall thickness, and compares them to the set specifications. If any deviation is found, the system adjusts the mold position, stretching mechanism and blowing parameters to correct the problem, ensuring that each batch of bottles meets high quality standards. This adaptive production system greatly reduces the need for manual intervention and fine-tuning, thereby improving production efficiency and product consistency.

2. Full-chain service ecology to ensure worry-free operation for customers

We are committed to building a comprehensive service ecosystem for our customers. Our pre-sales service includes in-depth market analysis and consultation. Our experts will not only introduce the characteristics and performance of the machine, but also gain insight into the latest trends in the beverage packaging industry, helping customers make informed decisions on equipment investment and production planning.

During the installation and commissioning phase, we provide turnkey solutions. Our team is responsible for the entire process from site preparation, equipment installation to system integration and initial testing. We also provide on-site training for operators and maintenance personnel, covering theoretical knowledge, practical operation skills and basic troubleshooting.

In terms of after-sales service, we have established a global service network and have local service centers. These centers are equipped with well-trained technicians to respond quickly to customer requests. We provide 24-hour remote technical support, and if on-site service is required, our technicians can reach the customer's location in the shortest time. We regularly arrange service visits to perform preventive maintenance, check equipment performance, and update software and control systems to ensure that the machine always operates at its best.

All in all, our PET automatic blow molding machine represents a major leap forward in the beverage packaging manufacturing industry. With its innovative technology, sustainable features, flexible production capabilities and comprehensive services, it provides a future-oriented solution for beverage and juice manufacturers. Embrace this cutting-edge equipment and enter a new era of smart, sustainable and efficient packaging production.

| TechnicalParameters | ZPA-1L-2 | ZPA-2L-2 | ZPA-1L-4 | ZPA-2L-4 | ZPA-1L-6 | ZPA-2L-6 | |

| Cavity | 2 | 2 | 4 | 4 | 6 | 6 | |

| Host Machine Parameter |

Clamping Force | 35000 | 45000 | 48000 | 48000 | 56000 | 65000 |

| Mold Route | 90 | 110 | 90 | 125 | 90 | 125 | |

| Stretching Rod Route | 300 | 400 | 260 | 330 | 260 | 330 | |

| Boctomn llold Route | 50 | 50 | 50 | 50 | 50 | 50 | |

| Bottle Spacing | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | |

| Bottle Preform Number | 66 | 52 | 95 | 82 | 106 | 92 | |

| Prodncts Parameter |

Max Capacty | 660 | 1500 | 600 | 1500 | 600 | 1500 |

| Max Bottle Boby Height | 260 | 330 | 260 | 330 | 260 | 330 | |

| Max Bottle Body Diameter | 68 | 105 | 68 | 105 | 68 | 105 | |

| MaxBottle Preformn Height |

100 | 140 | 100 | 140 | 100 | 140 | |

| Max Bottle Mouth Diameter |

38 | 38 | 38 | 38 | 38 | 38 | |

|

Eleetrical Parameter |

Capacty | 2500 | 2000 | 4500 | 4000 | 7200 | 6000 |

| Heating Oven Quantity | 2*2 | 4*4 | 4*4 | 5*5 | 4*4 | 5*8 | |

| Heating Lamp Quantity | 2*8 | 4*8 | 4*7 | 5*9 | 4*8 | 5*9 | |

| Heating Confguration Power | 32 | 48 | 42 | 72 | 64 | 90 | |

| Total Power Capedity | 32 | 48 | 42 | 72 | 64 | 90 | |

| Voltage | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | |

| Air source Parameter |

Worling Pressure | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| Blowing Pressure | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | |

| Air Capacitly Consumption | 2.4/30 | 2.4/30 | 3.6/30 | 3.6/30 | 5.0/30 | |

| Total Powwer | 30 | 30 | 45 | 45 | 60 | |

| Cooling Chiler Parameter | Ternperature | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 |

| Pressure | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Rated Power | 3 | 3 | 5 | 5 | 5 | |

| Dimenson | Host Machine Size | 2700*1800 | 3300*1800 | 3900*1800 | 4800*2200 | 4200*2100 |

、

、

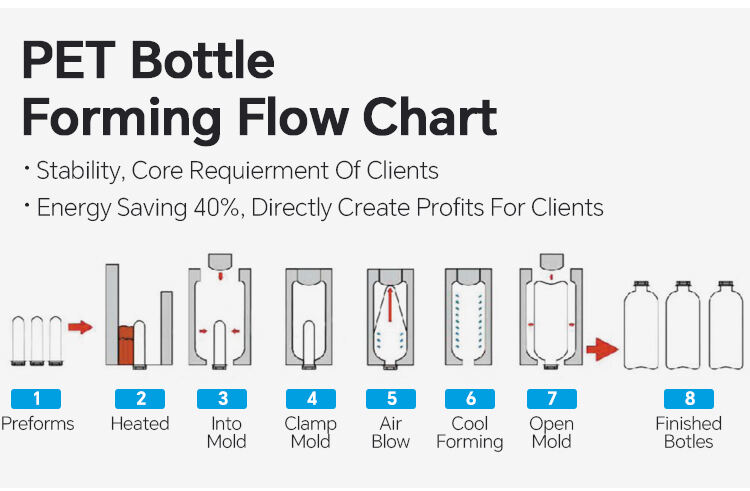

1 .stable and accurate running at high speed,adopt more stable and advanced micro-computer PLC control system.

2. production process is fully automated, with the advantages of low investment, highefficiency,easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range ofapplications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control. simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle.

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's ZOE PACK's advantage?

ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!