Cela semble être un processus très intéressant et important, celui du remplissage des bouteilles de shampoing. Placer le nombre exact d'onces de shampoing dans chaque bouteille vide, puis la sceller hermétiquement. Afin que le shampoing reste frais et prêt à l'emploi. Chaque bouteille ZOEPACK est remplie à la perfection. Nous souhaitons que nos clients utilisent nos produits quotidiennement sans aucune inquiétude.

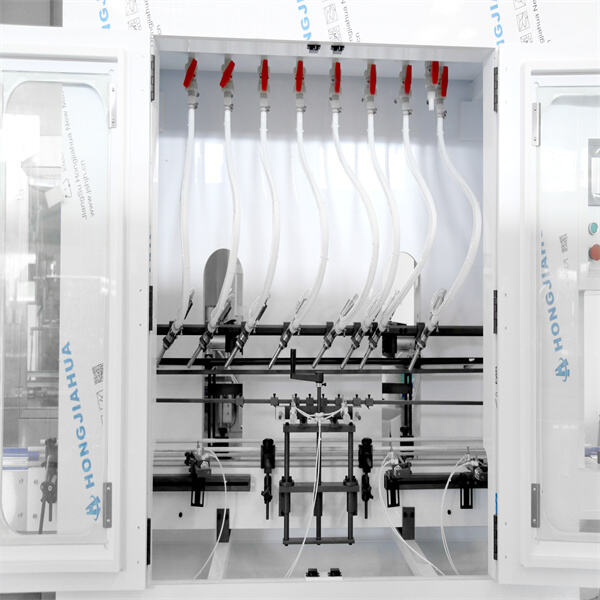

Chez ZOEPACK, le remplissage de shampoing commence par de grands contenants remplis de shampoing. Tout d'abord, nous mélangons le shampoing pour obtenir une mousse et un parfum parfaits. Ce mélange est extrêmement important car il garantit que toutes les bouteilles sont remplies d'un shampoing de haute qualité. Une fois le mélange terminé, nous transférons le shampoing vers une machine de remplissage. Le ZOEPACK machine de remplissage de shampoing ine distribue simplement la bonne quantité de shampooing dans chaque bouteille. Ensuite, une fois que nous avons rempli les bouteilles, nous les fermons hermétiquement pour éviter tout mélange ou fuite. Cela rend le shampooing sécurisé et le scelle jusqu'à ce que le produit parvienne au client.

Après que chaque bouteille ait été remplie de shampoing, elles descendent sur un tapis roulant. Il s'agit d'une seule voie mobile qui transporte les bouteilles à l'étape suivante. Pendant que les bouteilles se déplacent, nous imprimons notre logo ZOEPACK et des informations supplémentaires pertinentes pour les clients. (API) Le processus d'étiquetage est crucial car il informe le client sur ce qu'il achète. Après que les bouteilles ont été étiquetées, nous les plaçons ensuite dans des boîtes. Les boîtes sont ensuite emballées et expédiées aux magasins sous un format commercialisable.

Remplir des bouteilles de shampoing peut sembler être une tâche facile, mais le processus pour s'assurer que chaque bouteille est correctement remplie est une véritable science. ZOEPACK équipement de remplissage de shampoing distribue la bonne quantité de shampooing par machine. Cette programmation est conçue pour s'assurer que nos clients reçoivent toujours le meilleur produit. Nous devons bien faire les choses afin que personne ne soit déçu en utilisant notre shampooing.

Tout d'abord, les machines pour remplir le shampooing chez ZOEPACK sont très avancées et haute technologie. Une technologie spécialisée permet de remplir chaque bouteille avec précision et rapidité. Cela nous permet de remplir la majorité des bouteilles en un minimum de temps et sans erreur. Nos ZOEPACK machine automatique de remplissage et de fermeture de bouteilles sont également régulièrement entretenues pour s'assurer qu'elles fonctionnent toujours parfaitement. L'entretien régulier nous permet de prévenir les problèmes et de continuer à offrir des produits de qualité à nos consommateurs.

Préparation du mélange de shampooing : À l'étape un, nous mélangons les grands conteneurs de shampooing. Ce ZOEPACK machine d'emballage de shampooing est un outil essentiel pour s'assurer que la formule parfaite se retrouve dans chaque bouteille.

Mise en bouteille : Nous remplissons les seaux de 20 litres avec le 1300B, puis nous embouchons et scellons les bouteilles. Celles-ci portent également le logo ZOEPACK ainsi que les informations dont les clients ont besoin pour savoir qu'elles contiennent du shampoing.

Avant l'expédition, l'ensemble de nos équipements subit des tests rigoureux pour s'assurer qu'il n'y a aucun problème de qualité et pour répondre à nos normes strictes avant d'atteindre l'installation de notre client. Nous fournissons une assistance pour l'installation et la mise en service grâce à nos ingénieurs qualifiés afin de garantir un bon paramétrage et un fonctionnement fluide. En cas de problèmes, notre support en ligne est disponible pour aider au dépannage et à la communication en temps réel via des appels vidéo, aidant ainsi à résoudre rapidement les problèmes et réduire les temps d'arrêt. Nous recommandons également aux clients de visiter notre usine pour une formation pratique sur l'utilisation des équipements, où notre personnel offre un accompagnement complet et gratuit. Cet engagement envers le soutien client reflète notre engagement à bâtir de fortes relations et à garantir la satisfaction de nos clients.

Nos ingénieurs fournissent des services d'installation et de mise en service à l'étranger pour garantir un bon paramétrage et une exploitation sans accroc. Nos ingénieurs expérimentés peuvent fournir des services d'installation et de mise en service dans les pays étrangers pour assurer une exploitation fluide. Si nos clients rencontrent des problèmes, nous offrons un support en ligne 24/7 pour les aider à résoudre rapidement. Notre personnel fournira des instructions complètes et une assistance à tous les clients qui visitent notre installation. Notre engagement à aider nos clients démontre notre engagement à bâtir un fort conditionnement de shampooing et à garantir leur succès.

Notre équipe de conception travaille en étroite collaboration avec nos clients pour créer des bouteilles sur mesure conçues par nos clients. Nous prenons en compte des facteurs tels que la forme du matériau et l'utilisabilité pour créer une bouteille qui est fonctionnelle et esthétiquement plaisante. Nous proposons également un design de disposition expert pour les lignes de production. Nous créons des plans personnalisés aux dimensions spécifiques de votre espace de travail afin d'optimiser le stockage et les postes de travail, ce qui améliore l'efficacité et le flux de travail. Nous offrons également des conseils de conditionnement utiles en analysant les bons bouchons, le remplissage de shampoing en fonction du type de produit que vous vendez et des spécifications du marché pour vous assurer que votre produit est compatible, visuellement attractif tout en renforçant le message de votre marque. Nous pouvons vous aider à calculer les marges bénéficiaires en analysant les coûts locaux de production, de matériaux ainsi que la distribution. Notre équipe utilise des modèles financiers précis pour fournir des insights sur les stratégies de tarification, les marges bénéficiaires et les stratégies commerciales. Cela vous permet de prendre des décisions éclairées, d'optimiser votre stratégie globale et de garantir une croissance durable.

Comparé à la plupart des usines, notre équipement offre une vitesse de remplissage qui est presque 15 % plus rapide, améliorant considérablement l'efficacité en production et le débit. Notre équipement est conçu pour offrir une grande précision et stabilité. Nous respectons des normes strictes pour les spécifications et les dimensions. Notre engagement envers la qualité se reflète dans l'équipement que nous utilisons. Nous choisissons des fabricants renommés comme Alfa Laval et SMC. Ils sont connus pour leur fiabilité et leur efficacité dans le domaine. Notre système est conçu pour être durable et efficace, ce qui lui permet de fonctionner efficacement pour le remplissage de shampoing. Bien que d'autres installations puissent atteindre des débits allant jusqu'à 15 m/sec, la conception de notre système est axée sur l'efficacité et la durabilité, réduisant ainsi les coûts d'exploitation et d'entretien. La machine de remplissage que nous proposons est également un produit établi et éprouvé, avec de nombreux unités encore en service après plus de dix ans. Ce n'est pas seulement un indicateur de la durabilité à long terme de la machine, mais cela montre également notre engagement à fournir des solutions fiables dans un marché très compétitif.