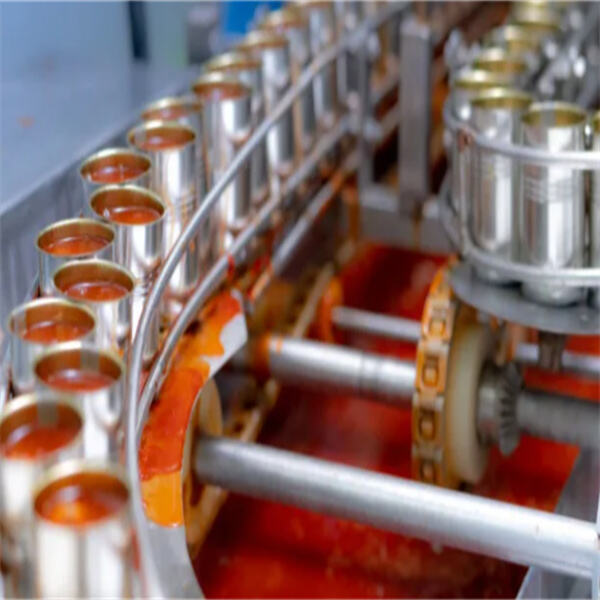

Ces machines de remplissage de sauce sont assez cool, ainsi que les produits ZOEPACK système de remplissage automatique de bouteilles elles aident à s'assurer que les sauces sont embouteillées précisément. ZOEPACK est une grande entreprise et ils produisent de très bonnes machines pour le remplissage de sauces. Voyons donc comment utiliser une machine à remplir des sauces pour améliorer des sauces délicieuses pour les gens.

Lorsque vous fabriquez votre sauce, avoir une machine de remplissage de sauce peut améliorer la manière dont vous créez votre sauce — la rendant plus facile et plus efficace pour remplir ces bouteilles, identique à machine de remplissage d'huile lubrifiante fabriquée par ZOEPACK. Une machine de remplissage de sauce de ZOEPACK peut vous aider à remplir les bouteilles de sauce plus rapidement et avec plus de précision. Cela signifie que vous pouvez produire une sauce encore plus délicieuse en moins de temps. Cela rendra votre travail plus facile et plus rapide, vous aidera à gagner plus d'argent et à satisfaire vos clients. Eh bien, en quelques minutes seulement, vous pourrez remplir un grand nombre de bouteilles et vos clients pourront suivre vos commandes.

Il existe de nombreux avantages à avoir une machine de remplissage de sauce dans votre ligne de production alimentaire, de même avec celle de ZOEPACK. machine de moulage de préformes en PET d'une part, il vous aide à gagner du temps et de l'argent en vous assurant de ne pas gaspiller de sauce. Il remplit chaque bouteille jusqu'au bord, sans débordement ni désordre. Cela signifie moins de nettoyage pour vous. Il s'assure également que vos sauces ont toujours la même taille, la même forme et le même goût. C'est important parce que lorsque vos clients achètent votre sauce, ils sauront ce qu'ils obtiennent. Les gens feront alors confiance à vos produits pour être toujours bons. Intégré avec des normes de sécurité, une machine de remplissage de sauce peut contribuer à rendre votre chaîne de production alimentaire plus sûre. Avec moins de déversements, les chances d'accidents ou d'erreurs sont réduites.

Cependant, pour que votre sauce soit remplie parfaitement à chaque fois, il vous faut la bonne machine pour remplir cette sauce. ZOEPACK produit des machines de qualité telles que machine de remplissage liquide volumétrique qui sont faciles à utiliser et très précis. Et pour que cette opération fonctionne parfaitement, vous avez besoin de la bonne machine ZOEPACK qui vous offre le même remplissage dans chaque bouteille de sauce à chaque fois. Cela signifie jour après jour, vos clients obtiennent sans aucun doute la meilleure sauce du coin. Cela aide à établir une bonne réputation pour votre entreprise.

Lors de l'achat d'une machine de remplissage de sauce, ZOEPACK est la solution à tous vos besoins en ligne de remplissage de sauce, ainsi que les produits ZOEPACK machine de moulage de bouteilles . Non seulement cela vous aidera à économiser des coûts avec le temps, mais cela peut également aboutir à une sauce délicieuse et des clients satisfaits. Imaginez à quel point il doit être agréable de savoir que votre sauce est toujours parfaitement remplie, peu importe combien de bouteilles vous devez remplir. C'est une étape importante pour faire croître votre entreprise et rendre plus de gens heureux avec vos excellentes sauces. Vos clients reviendront si ils sont satisfaits.

La machine de remplissage de sauce est soumise à des tests rigoureux avant l'expédition pour s'assurer qu'il n'y a aucun problème de qualité, afin de répondre aux exigences strictes avant d'atteindre l'installation du client. Nous offrons une assistance pour l'installation et le démarrage grâce à des ingénieurs expérimentés pour garantir un bon fonctionnement sans accroc. En cas de problèmes rencontrés par les clients, nous proposons un support en ligne via des communications en temps réel et la résolution de problèmes par appels vidéo, aidant ainsi à résoudre rapidement les questions et réduire les temps d'arrêt. Nous suggérons également que les clients visitent notre usine pour recevoir des instructions pratiques sur l'utilisation de l'équipement, où notre équipe fournit une assistance complète gratuitement. Cette dévotion au soutien client met en lumière notre engagement à bâtir de solides relations et à assurer le succès de nos clients.

Notre équipe de conception expérimentée travaille en étroite collaboration avec les clients pour développer des bouteilles personnalisées qui satisfont aux exigences fonctionnelles tout en correspondant à l'image de la marque, en prenant en compte des facteurs tels que la texture, le matériau et l'utilisabilité, pour des produits à la fois visuellement attractifs et pratiques. Nous offrons également un service d'aménagement expert des lignes de production, en concevant des plans adaptés aux dimensions de votre installation afin de maximiser l'espace de stockage et les postes de travail. Cela peut améliorer l'efficacité et le flux de travail. Nous proposons également des recommandations de conditionnement précieuses, en analysant les bouteilles, bouchons et étiquettes appropriés en fonction du type de produit que vous vendez et des exigences du marché, pour garantir une compatibilité et un attrait visuel tout en renforçant le message de votre marque. Pour soutenir votre réussite financière, nous aidons à calculer les points de profit en analysant les coûts locaux, y compris les matériaux, la production et la distribution. Notre équipe utilise des modèles financiers détaillés qui fournissent des informations sur la stratégie de tarification, les marges de profit et les stratégies commerciales. Cela vous permet de prendre des décisions éclairées et d'optimiser votre stratégie globale pour la machine de remplissage de sauce.

Avant que la machine de remplissage de sauce ne soit expédiée, tout équipement est soumis à des tests rigoureux pour s'assurer qu'il n'y a aucun problème de qualité et qu'il répond à nos standards d'excellence avant d'arriver sur le site du client. Nous offrons une assistance pour l'installation et la mise en service grâce à nos techniciens qualifiés pour garantir une installation correcte et un fonctionnement fluide. En cas de problèmes rencontrés par les clients, notre support en ligne est disponible en communication en temps réel et dépannage via des appels vidéo, aidant à résoudre rapidement les problèmes et à minimiser les temps d'arrêt. Nous recommandons également aux clients de visiter nos installations pour une formation pratique sur l'utilisation de l'équipement, où notre personnel fournit un accompagnement complet et gratuit. Notre engagement à aider nos clients témoigne de notre détermination à construire de solides relations avec nos clients et à assurer leur succès.

Comparativement à la majorité des usines, notre équipement a une vitesse de remplissage qui est presque 15 % plus rapide, améliorant considérablement la machine de remplissage de Sauce en termes de production et de débit. Nous nous conformons à des normes strictes pour les dimensions et spécifications de chaque composant, ce qui garantit que notre équipement offre une précision et une stabilité supérieures. Notre engagement envers la qualité est évident dans l'équipement que nous utilisons. Nous préférons des marques reconnues comme Alfa Laval et SMC. Elles sont réputées pour leur fiabilité et leur efficacité dans l'industrie. Bien que de nombreuses usines aient des débits pouvant atteindre 15 m/sec, notre conception se concentre sur la durabilité à long terme et l'efficacité, ce qui entraîne des coûts d'exploitation plus faibles et moins de besoins en maintenance. Notre machine de remplissage a une longue histoire, avec certaines unités encore en service depuis plus de 10 ans. Cela prouve la longévité de notre équipement, mais démontre également notre engagement à fournir des solutions fiables qui répondent aux besoins de nos clients dans un marché très compétitif.