Le processus de recharge des produits chimiques peut être délicat, sans parler potentiellement dangereux. Cependant, il est nécessaire de s'assurer que cela se fait rapidement et en toute sécurité pour tous, et de le faire correctement. C'est pourquoi la solution parfaite a été créée - une station de remplissage chimique conçue par des ingénieurs. Cette station dédiée offre un accès facile au rechargement des produits chimiques, tout en maintenant un focus sur la sécurité.

ZOEPACK reconnaît l'importance primordiale de la sécurité lors de la manipulation de produits chimiques pour s'assurer que celle-ci peut être renforcée lors de l'utilisation de produits chimiques. Le remplissage chimique est conçu avec des fonctionnalités de sécurité intégrées. Il dispose de lieux de stockage sûrs pour garder toutes les substances chimiques en toute sécurité, par exemple. Des instructions étape par étape, faciles à suivre, guident finalement les utilisateurs tout au long du processus de réapprovisionnement. Ces fonctionnalités aident tous les opérateurs à remplir les substances sans se soucier des accidents causés par des renversements ou des fuites. Ainsi, tout le monde peut travailler dans un espace sûr.

Notre station de recharge ne rend pas seulement vos produits chimiques plus sûrs, mais elle facilite également la recharge pour tous. Elle possède des étiquettes claires qui identifient précisément chaque produit chimique, ce qui permet de trouver facilement ce dont vous avez besoin. La station ZOEPACK dispose même de chambres de stockage classifiées où les produits chimiques sont entreposés, permettant ainsi aux utilisateurs de récupérer rapidement les produits chimiques nécessaires pour recharger leurs contenants. Cela leur fait gagner du temps en recherchant moins de fournitures et en se concentrant davantage sur leur travail. La station de remplissage rend le rechargement de produits chimiques simple et sans tracas pour n'importe qui.

L'entretien est essentiel pour que tout fonctionne correctement. Facile à entretenir, notre station de remplissage chimique fournit : elle a été conçue de cette manière afin que les employés n'aient pas besoin de fournir beaucoup d'efforts pour accéder à ses composants. Vous obtenez également des instructions simples sur la façon de prendre soin de la station de remplissage. Que ce soit remplacer des contenants ou nettoyer les zones de stockage, notre machine de remplissage chimique et station a été conçue pour que cela puisse être fait rapidement et facilement. Elle aide simplement tout le monde à maintenir efficacement la station sans interruption.

Le stockage et la manipulation corrects des produits chimiques dans le lieu de travail sont très importants pour s'assurer que tout le monde dans l'entreprise est en sécurité. Le équipement de remplissage chimique offre une tranquillité d'esprit car vos produits chimiques sont stockés et manipulés avec le plus grand soin. Notre installation dispose de systèmes pour prévenir les déversements et fuites. Cela aide à garder votre espace de travail propre et sûr, ce qui est vital pour tous ceux qui y travaillent. Tous peuvent travailler avec la certitude que les produits chimiques sont manipulés en toute sécurité.

Notre station de remplissage chimique est non seulement sûre et facile à utiliser, mais aussi conçue pour augmenter la productivité des travailleurs. Notre station ZOEPACK élimine toute distraction pour les employés en offrant un processus de recharge simple ainsi qu'un planning d'entretien aisé. Cela signifie moins d'arrêts, et les travailleurs peuvent profiter de journées de travail plus efficaces. Tout le monde peut accomplir son meilleur travail sans interruptions inutiles lorsque tout est organisé et facilement accessible.

Les ingénieurs de la station de remplissage chimique offrent des services d'installation et de mise en service internationale pour garantir un bon paramétrage et un fonctionnement fluide. Des ingénieurs experts sont capables de fournir des services d'installation et de mise en service dans des pays étrangers pour garantir un fonctionnement sans accroc. Si les clients rencontrent des problèmes, nous offrons un support en ligne pour aider à résoudre rapidement le problème. Nous suggérons également que les clients visitent l'usine pour recevoir des instructions pratiques sur l'utilisation de l'équipement, où notre équipe offre un soutien et un accompagnement complets gratuitement. Cet engagement à aider les clients démontre notre détermination à bâtir de solides relations avec nos clients pour assurer leur succès.

Avant que la station de remplissage chimique ne soit expédiée, tout l'équipement est soumis à des tests rigoureux pour s'assurer qu'il n'y a aucun problème de qualité et qu'il répond à nos standards d'excellence avant d'atteindre l'emplacement du client. Nous offrons une assistance pour l'installation et la mise en service grâce à nos techniciens compétents pour garantir une installation correcte et un fonctionnement fluide. En cas de problèmes rencontrés par les clients, notre support en ligne est disponible en communication en temps réel et dépannage via appels vidéo, aidant à résoudre rapidement les problèmes et à minimiser les temps d'arrêt. Nous recommandons également aux clients de visiter notre site pour une formation pratique sur l'utilisation de l'équipement, où notre personnel fournit un accompagnement et un soutien complets gratuitement. Notre engagement à aider nos clients témoigne de notre détermination à construire de solides relations avec nos clients et à nous assurer de leur succès.

Notre équipement remplit une station de remplissage chimique bien plus rapidement que la plupart des usines. Cela améliore l'efficacité de la production et de la productivité. Nous fixons des normes élevées pour les spécifications et les dimensions de chaque composant, ce qui garantit que notre équipement offre un haut niveau de fiabilité et de précision. Notre engagement en matière de qualité se reflète dans les composants que nous utilisons. Nous choisissons des marques renommées telles qu'Alfa Laval et SMC, connues pour leur fiabilité et leur efficacité dans l'industrie. Bien que de nombreuses usines aient des débits de 15 m/sec, notre conception met l'accent sur la durabilité à long terme et l'efficacité, ce qui entraîne des coûts d'exploitation plus faibles et des besoins en maintenance réduits. De plus, notre machine de remplissage a une longue histoire de réussite, avec certaines unités encore en fonctionnement après plus de 10 ans. Cela prouve la fiabilité de notre équipement, mais c'est aussi un signe de notre dévouement à fournir des solutions qui répondent aux besoins de nos clients dans un marché très compétitif.

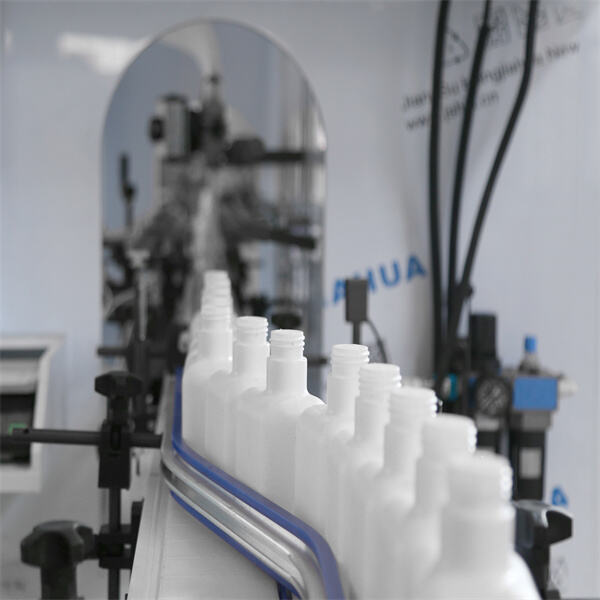

Notre équipe de conception d'experts travaille en étroite collaboration avec les clients pour créer des designs de bouteilles uniques qui répondent aux besoins fonctionnels mais qui s'accordent également avec l'image de la marque. Nous prenons en compte des facteurs tels que le matériau, la forme et l'utilisabilité afin de concevoir un produit à la fois visuellement attractif et pratique. Nous offrons également des services professionnels de mise en page et de conception de lignes de production, créant des diagrammes détaillés adaptés à la taille de l'espace de votre atelier pour optimiser l'emplacement des équipements, des postes de travail et des zones de stockage, ce qui améliore ainsi l'efficacité et le flux de travail. De plus, nous fournissons des conseils en matière d'emballage, en analysant les bouchons, bouteilles et étiquettes appropriés pour correspondre au type de produit que vous vendez et aux besoins du marché. Cela aide à garantir la compatibilité et l'attrait visuel tout en renforçant l'image de la marque. Nous pouvons également vous aider à calculer vos marges de profit en analysant vos dépenses locales, y compris la production, les matériaux et la distribution. Notre équipe utilise des modèles financiers détaillés pour vous donner une vue d'ensemble sur les marges de profit de la station de remplissage chimique et du plan d'affaires. Cela vous aide à prendre des décisions éclairées pour optimiser votre stratégie globale en vue d'une croissance durable.