How do we fill sauce bottles?

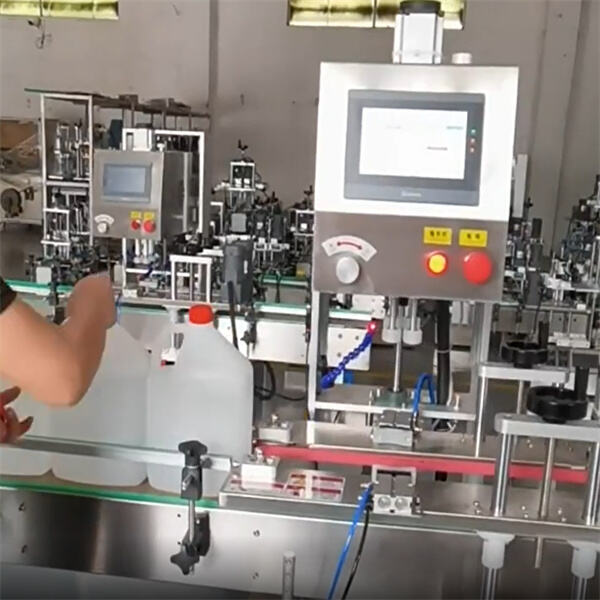

Ever wondered how sauces end up in bottles? This might sound like an easy job, but trust me, there is a lot of work behind it! ZOEPACK offers a great solution for small businesses who want to fill their sauces quickly and accurately. Manual sauce filling machines will precisely dispense your sauce into a bottle every time. This gives you a lot to fill your bottles without worrying about over or under filling them. You can use the hot sauce filling machine so easily. It is simple to use so you can learn to use it quickly and it is going to make your work a lot easier.

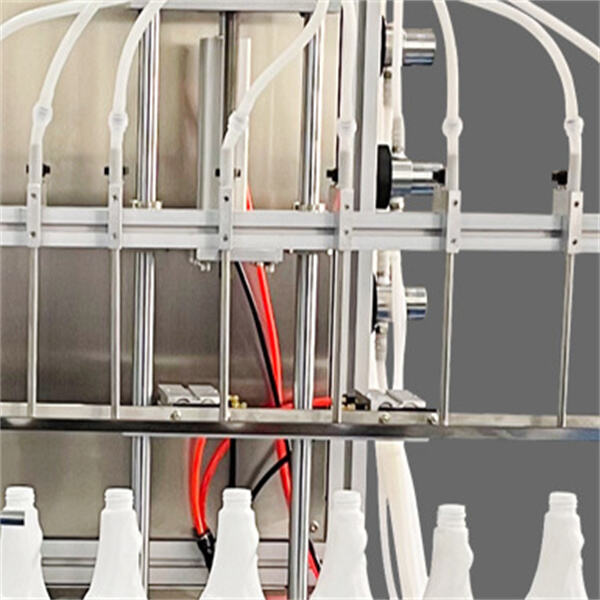

Not all sauces are created equal, and small businesses need to think outside of the box when it comes to filling their bottles, and ZOEPACK has a solution. Which is why our manual sauce filling machine gives you the ability to twist how the sauce comes out. This will allow you to control the flow of the sauce according to your needs. Whether it’s that thin line of sauce you drizzle on salads or a big scoop of sauce for dipping, this machine can do all of that. Easily set the controls to cater to whatever your sauce needs, so every bottle you fill is exactly how you want it. So, whatever sauce you are using, you always have the right amount, and your customers will be happy.

Even when filling up sauce bottles, it's still important to take care of our planet. They have also a good solution for small sauce production, their sauce bottle filler allows you to package a variety of sauces with ease and improve environmental impact. This machine enables you to reduce waste and save materials, so your sauce production is even more sustainable for our planet. If we get rid of waste, we can keep our earth clean and green. So while you fill bottles with delicious and tasty sauce, you’re also saving the planet. That’s a win-win situation.

Hand filling sauce bottles is a sloppy and time-consuming affair. It almost always spills and then can be an absolute nightmare to wipe off afterwards (frustrating). However, with sauce filling machine, you can accelerate and enhance your filling process. Of course, this machine will assist you to fill bottles quickly, so you can have more time for making delicious sauces for your customers. You can save a lot of time and energy, just imagine. No more spills or messes, just a smooth and easy filling process. You’ll be able to hit your savings later instead of just pouring bottles, all while improving your sauces and other things.

Filling their sauce bottles cheaply is often quite the challenge for small businesses. With wanting to grow your business, it can be hard to keep track of costs. But ZOEPACK is in no way is limited to hot sauces, with an affordable manual sauce filling machine that works for all sorts of sauces. This machine fills sauces of all consistencies, from thin dressings to thick marinades, which is ideal for a small batch with many types of sauce. This versatility is key; it means that you can rely on one machine for all your sauces and you won’t have to worry about spending money on multiple machines that each only does one task. Even at this low price point, this is a smart machine for any small business looking to ease their production. Your business will surely grow and thrive in no time with this investment.

Our engineers offer international installation and commissioning to ensure the proper setup and efficient operation Our highly skilled engineers are able to offer overseas installation and commissioning to assure smooth operation If clients have any issues we offer manual sauce filling machine to help resolve the issue promptly Our team will provide comprehensive support and training to customers who visit our factory This commitment to customer support emphasizes our desire to build strong relationships and guaranteeing the success of our customers

Our equipment fills nearly manual sauce filling machine more quickly than the majority of factories. This enhances the efficiency of production and productivity. We set high guidelines for the specifications and dimensions of every component, which ensures that our equipment provides high levels of reliability and accuracy. Our dedication to quality can be observed in the components we use. We select well-known brands such as Alfa Laval and SMC. They are well-known for their reliability and efficacy in the industry. While many factories have flows of 15m/sec, our design focuses on long-term durability and efficiency, which results in lower operational costs and reduced maintenance requirements. In addition, our filling machine has a long-standing track record, with some units still running for over 10 years. This proves the reliability of our equipment but is also a sign of our dedication to providing solutions that meet the needs of our customers in a highly competitive marketplace.

Prior to shipping all of equipment is manual sauce filling machine to rigorous testing to ensure that there are no quality issues to meet of excellence before it reaches the client's location. We provide installation commissioning assistance through experienced technicians to ensure proper installation smooth operation. If customers have issues we provide online support in real-time communications troubleshooting via video meetings helping to fix issues quickly minimize downtime. We also suggest that clients visit factory for h s-on training in equipment operation where staff provides comprehensive advice assistance for no cost. commitment to assist customers demonstrates commitment to build strong relationships with clients ensuring their satisfaction.

Our design team of experts works closely with clients to create unique bottle designs that fulfill functional needs but also match with the brand's branding. We consider factors such as the material, shape and usability in order to design a product that is both visually appealing and practical. We also provide professional layout and layout design services for production lines, creating detailed diagrams tailored to the size of your workshop's space to maximize equipment placement, workstations, and storage areas, thereby improving efficiency and workflow. Additionally, we provide packaging advice, analyzing suitable caps, bottles, and labels to match the type of product you are selling and needs of the market. This helps ensure compatibility and visual appeal and helps reinforce the brand's image. We can help you calculate profit margins by analyzing your manual sauce filling machine, including production, material, and distribution. Our team utilizes detailed financial models to give you insight into the pricing strategy, margins of profit, and the business plan. This helps you make informed decisions and to optimize your overall strategy for sustainable growth.