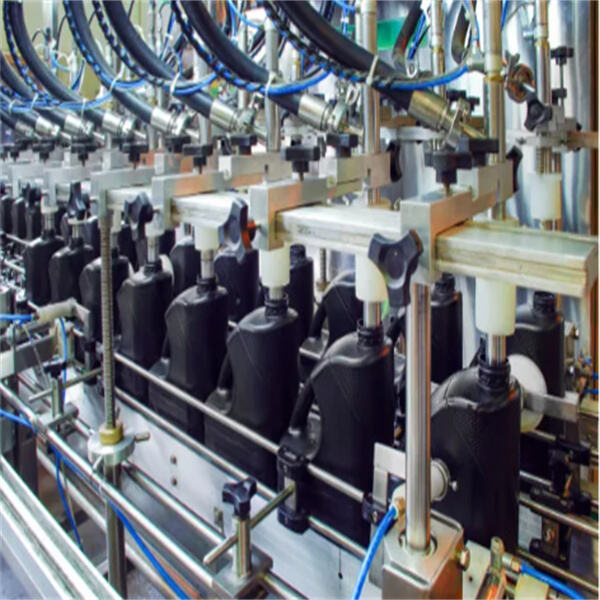

We are so proud to announce the launch of our awesome lubricant filling line at ZOEPACK. This is a special filling line which is designed to accelerate the productivity and improved quality of the products to be filled by companies. We know you need to do stuff fast while delivering top quality. This is why to fill containers as fast as possible, we have the latest technology on our filling line, for the best filling possible.

Lubricant Filling Line Features

Our lubricant filling machine has dozens of unique and special features compared to older filling lines. One of the key features is the autofill system. This is quite useful because it guarantees that the right amount of lubricant enters each container. Not only does this save a significant amount of time, but it reduces the chance of making any errors as well when filling the paper.

One of the best parts of our filling line is the capping machine. This automatic lubricant oil filling machine applies caps tightly on filled containers. This is extremely crucial in making sure that the lubricants are protected from dirt and spills. When the caps are in place, it helps avoid contamination or leakage, as well as maintain product efficacy in the process. We also have a labeling machine that labels the containers. These labels help in providing important information and allow the brand to be visible to everyone, which makes the entire process much faster and efficient.

Our lubricant filler line will ease your work so you can work at least beauty and handsome faster. With the automation system in this filling line, workers do not have to spend as much time doing manual work, which saves a lot of time and is more helpful for everyone to do their jobs. The production process runs smoother and is more efficient overall because workers can focus on other tasks that make money. In this way, they are able to devote their energy toward aspects of the job that need the most focus.

Plus, the lubricant filling line is easy to use and adopt. This implies your workers learn to use the machines in no time. It is always nice to have people who can incorporate these machines into their workflows with the most minimal of interruptions. However, the simple controls and clear instructions mean that workers can still operate the filling line without delay. This not only enhances the productivity but also ensures that the quality of products being produced is top-notch.

Producing a high quantity of goods is of utmost importance in manufacturing, and we at ZOEPACK understand this very well. why our lubricant filling line as well as lubricant oil packing machine is designed to enable you to produce more products while minimizing downtime. Our high-speed filling line allows you to fill numerous containers in just a few minutes, massively increasing your overall production.

With a lubricant filling line from us, you can also rely on it; with us, your lubricant oil filling machine always runs. This stability is crucial to upholding the positive reputation of your brand. As new customers only see reliable products they know they can trust, this inspires commitment and decisions to return. Our filling line offer you an output maximization, which allows you to meet customer needs and grow your business effectively.

Our engineers provide international installation and commissioning services to ensure Lubricant filling line and smooth operation. Our highly skilled engineers are able to offer overseas installation and commissioning to ensure smooth operation. If customers have any issues, we offer online support to assist in resolving problems promptly. Our team of experts will provide extensive assistance and training for customers who visit our factory. Our dedication to customer service is a testament to our commitment to establishing strong relationships and guaranteeing the success of our clients.

As compared to most factories our equipment has a filling speed that is nearly 15% quicker greatly increasing efficiency and production Our equipment is designed to ensure high accuracy and stability We adhere to stringent requirements in terms of the specifications and sizes This commitment to excellence is reflected in the choice of components; we utilize well-known brands such as Alfa Laval SMC DANFOSS and Schneider who are well-known for their reliability and effectiveness in the industry Our water treatment system is designed for durability with a flow rate of 8m/sec and the ability to operate effectively over extended periods The system we use is designed to be robust and effective allowing it to operate efficiently for longer periods Although other factories reach flow rates as high as 15m/sec the design of our system prioritizes efficiency and longevity reducing operating costs and maintenance needs In addition our Lubricant filling line has a track record of success and some machines have been running for over 10 years This isn't just an indication of the durability of the equipment but also of our commitment to providing reliable solutions in a highly competitive market

Our design team works closely with our customers to create custom bottles that are designed by our clients. We consider factors such as the material, shape, and usability to create a bottle which is both functional and aesthetically pleasing. We also offer expert layout design for production lines. We create plans that are customized to the specific dimensions of your work space to optimize storage and workstations. This will enhance efficiency and workflow. We also offer helpful packaging advice, by analyzing the right caps, bottles and labels in accordance with the type of product you are selling and market specifications to make sure that your product is compatible and visually appealing while enhancing your Lubricant filling line. We can help you calculate profit margins by analyzing the local costs of production, material, as well as distribution. Our team employs precise financial models to provide insights into pricing strategies, profit margins, and business strategies. This allows you to make informed choices and optimize your overall strategy to ensure sustainable growth.

Our engineers offer international installation and commissioning to ensure the proper installation and Lubricant filling line. We provide installation and commissioning through our highly skilled engineers to ensure a proper setup and seamless operation. If customers experience issues, we provide online support in real-time communications and troubleshooting via video meetings, helping resolve issues swiftly and minimize downtime. Our team provides comprehensive training and support to clients who visit our facility. This commitment to customer support underscores our dedication to building solid relationships and ensuring our clients' satisfaction.