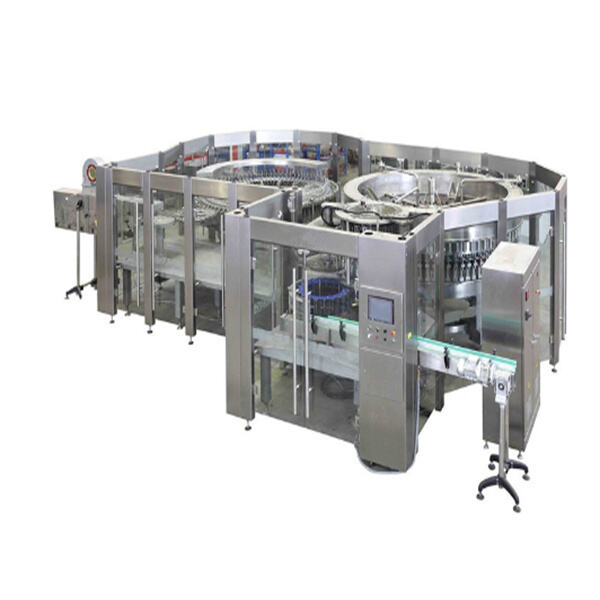

If you have a factory working on dish wash liquid, you know that with the means to improve and make your work customizable can make your methods faster and effective. Now, If you own a factory, then there is one machine that you should definitely have which is the dish wash liquid filling machine from ZOEPACK. You can fill your bottles with the help of this machine and all that in a very smooth manner.

A dish wash liquid filling machine is a specialized piece of equipment used to automatically fill bottles with liquid soap at high speed. From this machine that fills many bottles at the same time, helps your factory save a lot of time. You won’t have to fill each bottle up one by one — it gets done for you, which lets you create more products in much less time. When you are working with a ZOEPACK automatic filling machine for liquid, you can control the speed of the filling process as well as the amount of liquid filling into the bottles. That way, you’re free to do the process that works for you, best, as there is no one right way to plan retreat.

Speed and accuracy are some of the most significant advantages of using a dish wash automatic liquid filling and sealing machine. These specialist pieces of equipment use a special technology that guarantees each and every bottle is filled to the exact same level every time. This is useful because it saves you from wasting — which means you won’t discard excess soap that drips off. You also increase the overall quality of your product, which is more consistent for your customers. If your customers know they can rely on your product to be the same from one experience to the next, they’re more likely to purchase it again.

A dish wash automatic liquid packaging machine from ZOEPACK can save your time and money as well. Letting the machine fill the bottles can enable your workers to spend their time on other essential work in the factory, rather than wasting hours filling bottles. This saves you money on labor costs as you do not require as many workers to perform this task. Also, since these machines fill the bottles precisely, you will lose less product through spills or overfilling. Such costs will be further reduced, thus providing an even more expensive machine, which is a wise investment for your factory, in the long run.

Each bottle needs the correct amount of dish wash liquid in it to make it a quality product. All you need to do is install a dish wash electronic liquid filling machine by ZOEPACK. This machine guarantees a consistent fill level and the precise application of fill level for each individual bottle. It enables you to set a high bar and fit in, meaning that your customers are happy with the use of your product.

Filling Machine is must-have if you are packing Dish Wash Liquid. ZOEPACK dish wash liquid filling machines are designed to be, robust and reliable manufacturers you can trust for your packaging requirements. They are designed with features that aid in proper care and user experience which means your employees will be able to use them without much difficulty. This would cause your production process to be seamless and thus increasing your factory efficiency.

Comparatively to the majority of factories, our equipment is able to fill at a Dish wash liquid filling machine that is nearly 15% quicker, drastically increasing efficiency and production. We adhere to strict standards for the specifications and dimensions of all components, making sure that our equipment delivers superior precision and stability. Our dedication to quality can be observed in the components we utilize. We select well-known brands like Alfa Laval and SMC. They are recognized for their reliability and effectiveness in the field. Although many factories can achieve flow rates of 15m/sec or more, our system's design prioritizes longevity and efficiency, contributing to lower operational costs and fewer maintenance needs. Our filling machine is an established and tried product which is why many of them are being used after more than 10 years. This longevity not only demonstrates the longevity of our equipment, but additionally demonstrates our commitment to providing reliable solutions that satisfy the demands of our clients in a highly competitive marketplace.

Our engineers offer international installation and commissioning services to ensure a proper setup and efficient operation. Our skilled engineers are able to provide overseas installation and commissioning to ensure smooth operation. If our customers encounter any issues, we offer online assistance to resolve the issue promptly. Our staff will provide complete instruction and assistance to all customers who visit our factory. This commitment to support our customers Dish wash liquid filling machine our commitment to build strong relationships with clients and to ensuring their success.

Our engineers offer Dish wash liquid filling machine and commissioning to ensure the proper setup and efficient operation. We offer overseas installation and commissioning services through our skilled engineers to ensure correct setup and seamless operation. If customers encounter issues, we provide online support for real-time communication and troubleshooting via video calls, helping resolve issues swiftly and minimizing downtime. We also suggest that clients visit our facility for hands-on training in equipment operation, where our experts provide comprehensive guidance and support at no cost. Our dedication to customer service emphasizes our desire to build solid relationships and ensuring the success of our customers.

Dish wash liquid filling machine professional design team collaborates closely with clients to create customized bottle designs that not only meet functional needs but also match with the br 's br ing taking account factors like the material shape usability to create the product to be aesthetically pleasing practical. Additionally we offer an expert layout plan for your production line by creating precise diagrams that are tailored to the size of your workshop's space for optimal placement of equipment workspaces workstations storage spaces thus enhancing productivity workflow. We also provide packaging guidance analyzing the best caps bottles labels according to your product type the marketplace requirements. helps ensure the compatibility of your product its visual appeal while reinforcing br message. To help you achieve financial success we help in calculating profit points through taking account local costs such as materials production distribution. Our team of experts utilizes thorough financial models to give you insights the pricing strategy margins of profit the business plan. helps you make informed choices optimize your overall strategy to ensure sustainable growth.