4 Cavilities Full Automatic Bottle Molding Machine

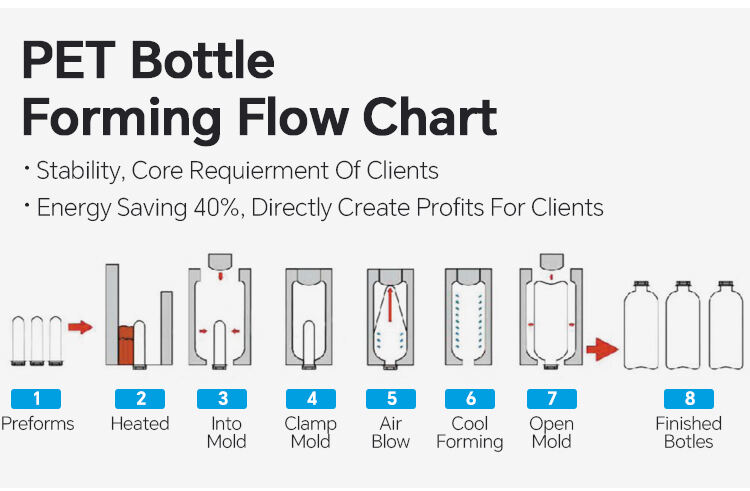

Adopt touch -type color HMl systems as to operate. Can blow maximum 10 literbottles. Maximum production speed can be 1500 bottles/hour.

Applicable to all kinds of PET botles which used for oll, soft drinks, mineral wa-ter,wine,medicine.cosmetics.etc.

In the highly competitive beverage and juice industry, the quality and efficiency of packaging are critical to the success of the product. Our PET automatic blow molding machine designed specifically for beverages and juices is a revolutionary solution that combines cutting-edge technology, intelligent control systems and high-performance features to meet the diverse needs of modern beverage manufacturers.

High-precision automated control system

Our PET automatic bottle blowing machine is equipped with an advanced automated control system that incorporates high-precision sensors, advanced control algorithms, and real-time data processing technology. The equipment is equipped with a variety of sensors, including temperature sensors, pressure sensors, displacement sensors, and force sensors, which can continuously monitor key process parameters. These sensors provide accurate and reliable data, with pressure measurement accuracy up to ±0.5% and displacement measurement accuracy up to ±0.1 mm.

The control system is based on a programmable logic controller (PLC), equipped with a high-performance processor and a user-friendly human-machine interface (HMI). The PLC executes a series of complex control algorithms designed to keep the equipment in optimal operation. For example, the temperature control algorithm uses a combination of proportional-integral-derivative (PID) control and adaptive control strategies to accurately adjust the heating temperature of the preform. This ensures that the temperature remains stable even when production conditions change, such as changes in ambient temperature or preform feed speed.

In addition, the equipment is equipped with an advanced process monitoring and fault diagnosis system. The system analyzes sensor data in real time and uses machine learning algorithms to detect any anomalies or potential faults. If a problem is found, the system can automatically take corrective measures, such as adjusting process parameters or shutting down the machine to prevent damage. This proactive approach to maintenance significantly reduces downtime and ensures continued reliable operation of the production line.

| TechnicalParameters | ZPA-1L-2 | ZPA-2L-2 | ZPA-1L-4 | ZPA-2L-4 | ZPA-1L-6 | ZPA-2L-6 | |

| Cavity | 2 | 2 | 4 | 4 | 6 | 6 | |

| Host Machine Parameter |

Clamping Force | 35000 | 45000 | 48000 | 48000 | 56000 | 65000 |

| Mold Route | 90 | 110 | 90 | 125 | 90 | 125 | |

| Stretching Rod Route | 300 | 400 | 260 | 330 | 260 | 330 | |

| Boctomn llold Route | 50 | 50 | 50 | 50 | 50 | 50 | |

| Bottle Spacing | 76.2 | 114.3 | 76.2 | 114.3 | 76.2 | 114.3 | |

| Bottle Preform Number | 66 | 52 | 95 | 82 | 106 | 92 | |

| Prodncts Parameter |

Max Capacty | 660 | 1500 | 600 | 1500 | 600 | 1500 |

| Max Bottle Boby Height | 260 | 330 | 260 | 330 | 260 | 330 | |

| Max Bottle Body Diameter | 68 | 105 | 68 | 105 | 68 | 105 | |

| MaxBottle Preformn Height |

100 | 140 | 100 | 140 | 100 | 140 | |

| Max Bottle Mouth Diameter |

38 | 38 | 38 | 38 | 38 | 38 | |

|

Eleetrical Parameter |

Capacty | 2500 | 2000 | 4500 | 4000 | 7200 | 6000 |

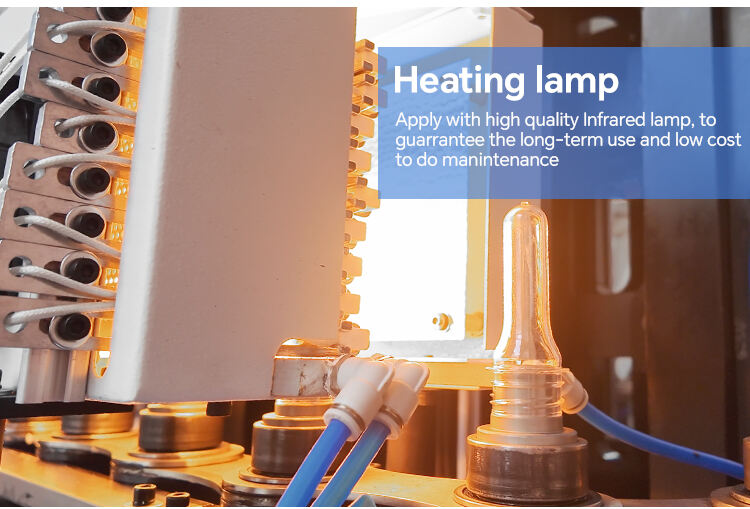

| Heating Oven Quantity | 2*2 | 4*4 | 4*4 | 5*5 | 4*4 | 5*8 | |

| Heating Lamp Quantity | 2*8 | 4*8 | 4*7 | 5*9 | 4*8 | 5*9 | |

| Heating Confguration Power | 32 | 48 | 42 | 72 | 64 | 90 | |

| Total Power Capedity | 32 | 48 | 42 | 72 | 64 | 90 | |

| Voltage | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | 380V50HZ | |

| Air source Parameter |

Worling Pressure | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 | 0.7-0.9 |

| Blowing Pressure | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | 2 5-3.0 | |

| Air Capacitly Consumption | 2.4/30 | 2.4/30 | 3.6/30 | 3.6/30 | 5.0/30 | |

| Total Powwer | 30 | 30 | 45 | 45 | 60 | |

| Cooling Chiler Parameter | Ternperature | 9-13 | 9-13 | 9-13 | 9-13 | 9-13 |

| Pressure | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | |

| Rated Power | 3 | 3 | 5 | 5 | 5 | |

| Dimenson | Host Machine Size | 2700*1800 | 3300*1800 | 3900*1800 | 4800*2200 | 4200*2100 |

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's ZOE PACK's advantage?

ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!