Mail Us: [email protected]

Call For Us: +86-512 58990369

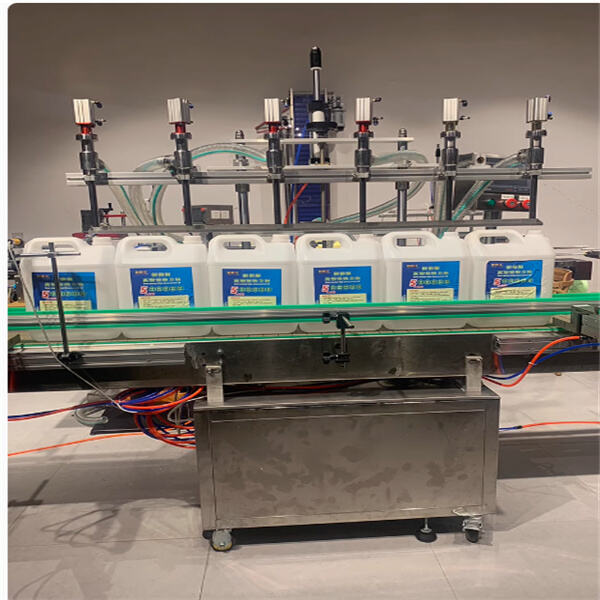

ZOEPACK liquid detergent packaging machine is a unique machine used to fill liquid detergent into packages. In factories where liquid detergent is produced, this machine plays a critical role as it speeds up and makes the job easier. Just about everyone works in factories nowadays, and they want tools that will help them do their jobs better. Here’s some information about how this machine works and why it is so useful for all those involved.

There are carton packing machines and detergent packing machine that accelerate the work in the factory. And it can fill containers with liquid detergent at a rapid pace. That means workers save significant time and effort. A faster process enables the factory to jar up more liquid detergent over a shorter period of time. This is also good for productivity, as it means that the plant can produce and package more items. With the ZOEPACK machine designed to automate processes, everything works much smoother, with little room for error and delays. In a busy factory, where people try to complete their work as effectively as possible, this is very important.

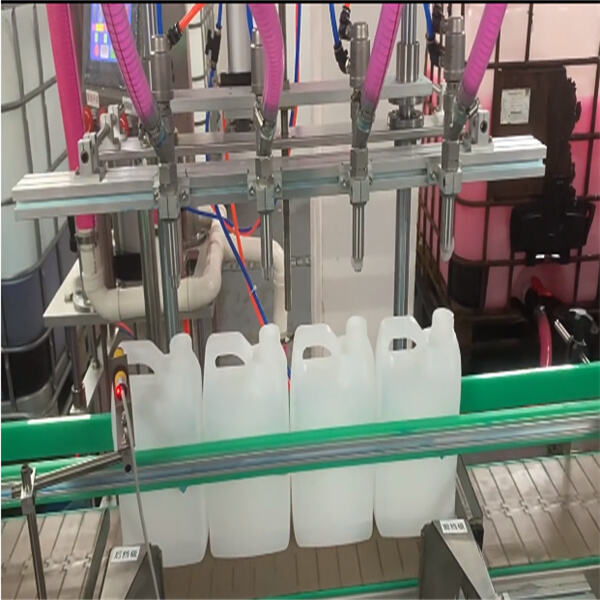

We know well regarding the needs of factories in terms of liquid detergent packaging and liquid detergent filling machine, at ZOEPACK. Others may have smaller containers to fill, while some manufacturers might have large containers to fill. That is why we are providing specific options on our machines. So whether you are looking for a machine for tiny bottles or larger jugs, we have the perfect selection for your needs. Customized Liquid Detergent Packaging Machine Our team of experts can help you adapt the liquid detergent packaging machine to your exact needs. That means that it would work just fine in your factory, doing its best to keep things running smoothly.

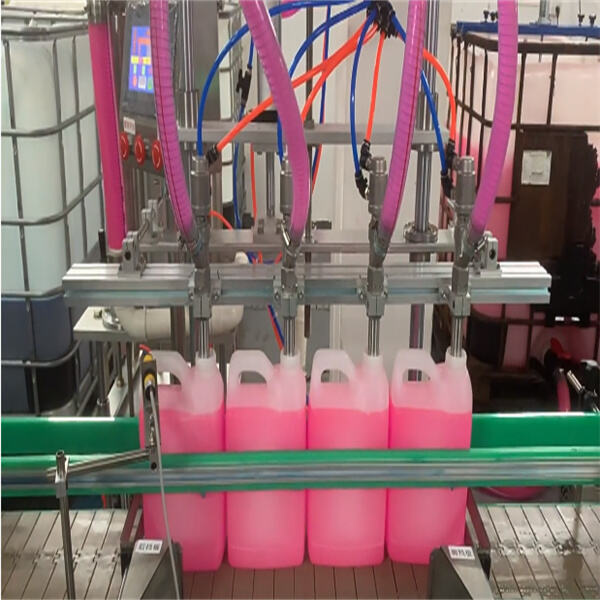

Measuring, dispensing, filling, capping, and sealing are some of the most critical packaging operations in the liquid detergent packaging process. If they are inaccurate, customers could be using more or less detergent than they need. So the liquid detergent packaging machine as well as detergent filling machine from ZOEPACK will give you a high level of confidence that each and every container will be filled to the right volume and well sealed. This prevents any leakage or spillage during shipping or handling. It is imperative to have the quality of the liquid detergent intact when it reaches the consumers at any given point of shipment while building trust in the minds of the consumers to be repeated in the process of the next order.

ZOEPACK laundry detergent filling machine and liquid detergent packaging machine can help your factory package more liquid detergent in less time. This means you are able to fulfil orders quicker and stay ahead on what customers want without any downtime. Because it is a fast and efficient machine, the machine allows you to pack more containers in a shorter time. This is awesome as per the customer’s demand to cater. Furthermore, the packing machine for liquid detergent is made to be durable and durable. This minimizes the risk of unexpected breakdowns or malfunctions that could delay production in the factory. When the machines are doing their job, though, everyone can do their job.

It is extremely important to keep pace with the latest developments in packaging technology to ensure that your factory remains closely behind other factories in the business. We are constantly working to enhance and modernize the liquid detergent packaging machine from ZOEPACK to stay ahead of the industry. Investing in liquid detergent packaging machines that provide the most current technology will keep your factory up-to-date with market needs. So you continue to learn ahead of your competitors. Using ZOEPACK's liquid detergent packaging machine, you can be sure that you are using high tech for liquid detergent packaging in an efficient and effective manner, ensuring that everything goes without a hitch.

Before Liquid detergent packaging machine, all equipment is subjected to rigorous testing to ensure no quality issues and to meet our standards of excellence before it reaches the client's location. We offer installation and commissioning assistance through our knowledgeable technicians to ensure proper installation and a smooth operation. If customers encounter issues our online support is available in real-time communications and troubleshooting via video calls, helping to solve issues quickly and minimize downtime. We also recommend that customers visit our facility for hands-on training in equipment operation, where our staff provides comprehensive guidance and support at no cost. Our commitment to assist our customers is a sign of our commitment to building strong client relationships and ensuring that they are successful.

Compared to Liquid detergent packaging machine, our equipment has a filling rate that is almost 15% quicker, drastically increasing efficiency and production. Our equipment is built to ensure high accuracy and stability. We adhere to rigorous standards in terms of specifications and dimensions. This commitment to quality is reflected in the choice of components We use well-known brands such as Alfa Laval, SMC, DANFOSS, and Schneider, which are renowned for their dependability and performance within the industry. Our water treatment system has been made to last with a flow rate of 8m/sec, allowing it to operate effectively over extended periods. While many factories have flow rates of up to 15m/sec our system's design prioritizes longevity and efficiency, which results in lower operating costs and less maintenance requirements. The filling machine we offer is also proven and tested which is why many of them are being used after more than ten years. This isn't just an indication of the quality of our equipment and our determination to offer reliable solutions in a highly competitive market.

Liquid detergent packaging machine professional design team collaborates closely with clients to create customized bottle designs that not only meet functional needs but also match with the br 's br ing taking account factors like the material shape usability to create the product to be aesthetically pleasing practical. Additionally we offer an expert layout plan for your production line by creating precise diagrams that are tailored to the size of your workshop's space for optimal placement of equipment workspaces workstations storage spaces thus enhancing productivity workflow. We also provide packaging guidance analyzing the best caps bottles labels according to your product type the marketplace requirements. helps ensure the compatibility of your product its visual appeal while reinforcing br message. To help you achieve financial success we help in calculating profit points through taking account local costs such as materials production distribution. Our team of experts utilizes thorough financial models to give you insights the pricing strategy margins of profit the business plan. helps you make informed choices optimize your overall strategy to ensure sustainable growth.

Our engineers provide overseas installation and Liquid detergent packaging machine services to ensure a proper setup and efficient operation. Our experienced engineers can provide installation and commissioning services in foreign countries to ensure smooth operation. If clients encounter problems, we provide online assistance to resolve them promptly. We also recommend that customers visit our factory for hands-on training in equipment operation, where our team provides complete assistance and guidance for no cost. This commitment to customer support underscores our dedication to building strong relationships, and to ensuring our clients' satisfaction.

Please feel free to let us know if you need any help,we will provide a professional guidance for youl

CONTACT US